Volkswagen ID.4: Rear axle

- Overview of fitting locations - rear axle

- Removing and installing rear axle

- Lowering rear axle

- Securing vehicle to support arms of lifting platform

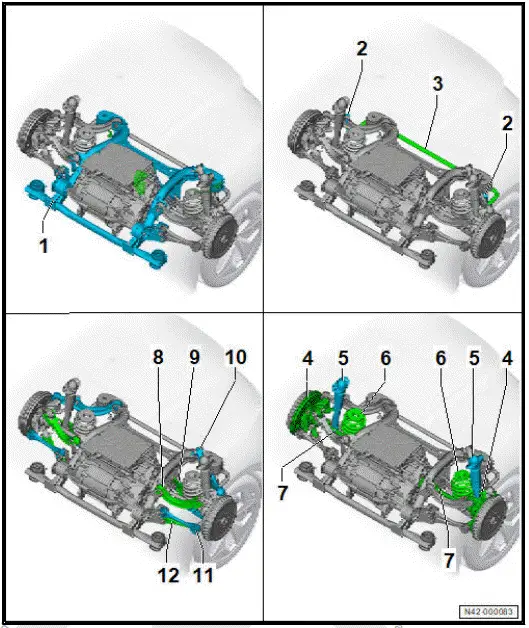

Overview of fitting locations - rear axle

- Subframe

- ⇒ Rep. gr. 42 ; Assembly overview - subframe

- ⇒ Rep. gr. 42 ; Taking up weight of subframe using scissor-type assembly platform

- ⇒ Rep. gr. 42 ; Removing and installing rear axle

- Coupling rod

- ⇒ Rep. gr. 42 ; Assembly overview - antiroll bar

- ⇒ Rep. gr. 42 ; Removing and installing coupling rod

- Anti-roll bar

- ⇒ Rep. gr. 42 ; Assembly overview - antiroll bar

- ⇒ Rep. gr. 42 ; Removing and installing anti-roll bar

- Wheel bearing housing

- ⇒ Rep. gr. 42 ; Assembly overview - wheel bearing

- ⇒ Rep. gr. 42 ; Removing and installing wheel bearing housing

- Shock absorbers

- ⇒ Rep. gr. 42 ; Assembly overview - shock absorber

- ⇒ Rep. gr. 42 ; Removing and installing shock absorber

- Spring

- ⇒ Rep. gr. 42 ; Assembly overview - spring

- ⇒ Rep. gr. 42 ; Removing and installing spring

- Drive shaft

- ⇒ Rep. gr. 42 ; Assembly overview - drive shaft

- ⇒ Rep. gr. 42 ; Removing and installing drive shaft

- Upper link (front)

- ⇒ Rep. gr. 42 ; Assembly overview - suspension link

- ⇒ Rep. gr. 42 ; Removing and installing upper front suspension link

- Spring control arm

- ⇒ Rep. gr. 42 ; Assembly overview - spring control arm

- ⇒ Rep. gr. 42 ; Removing and installing spring control arm

- Upper rear suspension link

- ⇒ Rep. gr. 42 ; Assembly overview - suspension link

- ⇒ Rep. gr. 42 ; Removing and installing upper rear suspension link

- Track rod

- ⇒ Rep. gr. 42 ; Assembly overview - track rod

- ⇒ Rep. gr. 42 ; Removing and installing track rod

- Lower suspension link

- ⇒ Rep. gr. 42 ; Assembly overview - suspension link

- ⇒ Rep. gr. 42 ; Removing and installing lower suspension link

Removing and installing rear axle

Special tools and workshop equipment required

- scissor-type assembly platform - VAS 6131B-

- tensioning strap - T10038-

Removing

- Remove motor ⇒ Rep. gr. 10 ; Removing and installing rear motor; Removing rear motor .

- Remove springs ⇒ Rep. gr. 42 ; Removing and installing springs .

- Remove rear wheel housing liners ⇒ General body repairs, exterior; Rep. gr. 66 ; Wheel housing liner; Removing and installing rear wheel housing liner .

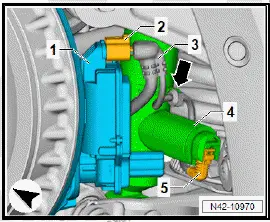

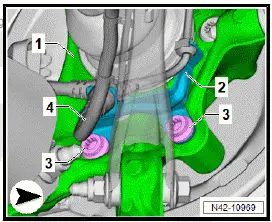

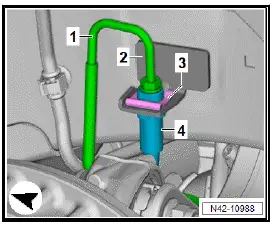

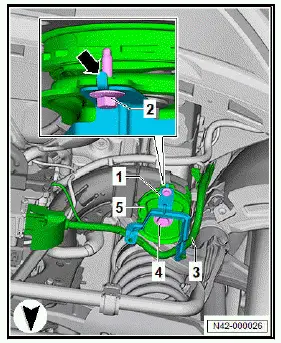

- Disconnect electrical connector -2- on left parking brake motor - V282- and on right parking brake motor - V283- -1-.

Vehicles with adaptive chassis control

- Disconnect electrical connector -3- on rear left shock absorber damping adjustment valve - N338- and on rear right shock absorber damping adjustment valve - N339- .

- Pull electrical wire off retainer on shock absorber -2- on both sides of vehicle -arrow-.

All vehicles (continued)

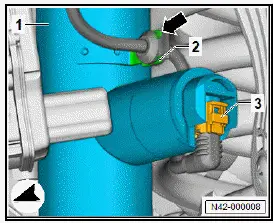

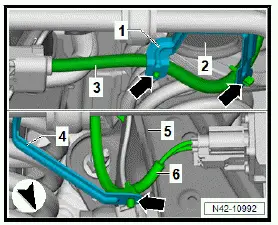

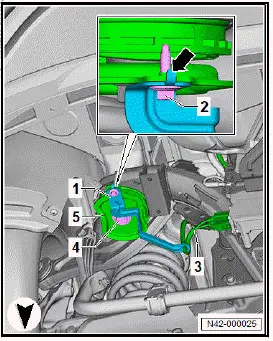

- Disconnect electrical wire -3- on rear left vehicle level sender - G76- -4-.

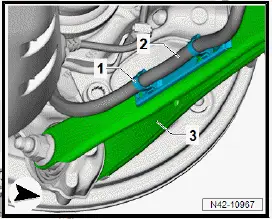

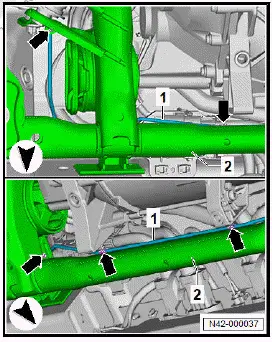

- Pull off electrical wire -2- on rear axle -1- -arrow-.

- Pull electrical wire -4- off retainer -2-.

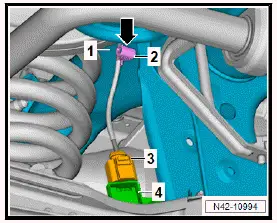

- Unclip retainer -1- for electrical wire -2- from lower suspension link -3-.

- To do this, press together locking lugs of retainer -1- at inside of lower suspension link -3-.

- Pull electrical wire -3- off retainer -4- on both sides of vehicle.

- Unclip electrical wire -3- from rear axle -1- on both sides of vehicle -2-.

- Disconnect electrical connector -2- on rear left speed sensor - G46- and on rear right speed sensor - G44- -3-.

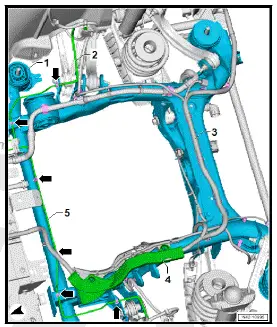

- Pull retaining clip -3- off brake hose -4- on both sides of vehicle.

- Unscrew brake line -1- on both sides of vehicle.

- Pull brake hose -4- out of retainer -2- on both sides of vehicle.

- Unclip electrical wire -3- from retainer -1- on right side of vehicle -arrows-.

- Unclip electrical wire -6- from retainer -4- on left side of vehicle -arrow-.

For greater clarity, the illustration shows the rear axle from above.

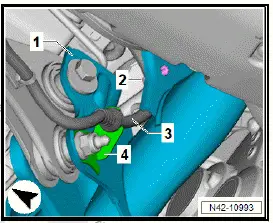

- Completely detach electrical wire -3- on rear axle -1-, and move it aside.

- Unclip brake lines -5- on rear axle -1- from retainers -arrows-.

- Pull cable guide -4- upwards off rear axle -1-.

- Secure electrical wire and brake lines to vehicle using suitable workshop materials.

- ⇒ Rep. gr. 42 ; Fix subframe in position .

- Unscrew bolts -3- for shock absorbers -4- and -5-.

- ⇒ Rep. gr. 42 ; Take up weight of subframe using scissortype assembly platform .

NOTICE

Risk of lines becoming damaged due to limited space.

- When lowering, ensure sufficient clearance to brake lines and electrical wiring.

- Lower subframe with attachments using scissor-type assembly platform - VAS 6131B- .

- Use a tensioning strap - T10038- to secure subframe to scissor-type assembly platform - VAS 6131B- .

- Lower subframe with attachments further using scissor-type assembly platform - VAS 6131B- .

Installing

Install in reverse order of removal, observing the following:

- Carry out required function/functions using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

- ⇒ Rep. gr. 44 ; When does wheel alignment have to be checked?

Tightening torques

- ⇒ Rep. gr. 42 ; Assembly overview - subframe

- ⇒ Rep. gr. 42 ; Assembly overview - shock absorber

Lowering rear axle

Lowering rear axle, front section

Special tools and workshop equipment required

- engine and gearbox jack - VAS 6931-

- gearbox support - T10337-

- Remove rear underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing rear underbody cladding .

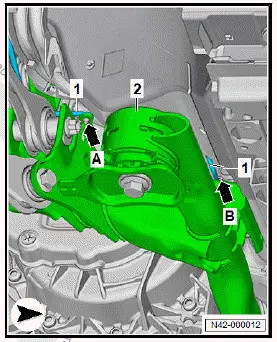

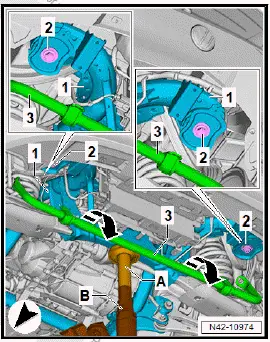

- Unclip brake line -1- on right side of subframe -2- -arrow Aand -arrow B-.

- Unclip brake line -1- on left side of subframe -2- -arrows-.

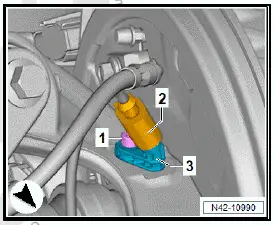

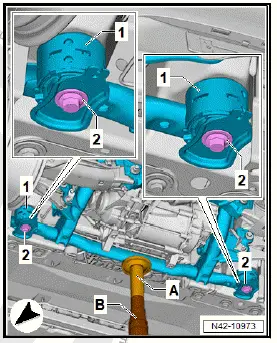

- Fit gearbox support - T10337- -A- onto engine and gearbox jack - VAS 6931- -B-.

- Position gearbox support - T10337- -A- on subframe -1-.

- Support subframe -1- with engine and gearbox jack - VAS 6931- -B-.

- Unscrew bolts -2- from subframe -1- on both sides of vehicle.

NOTICE

Risk of damage to electrical wires, hoses and connections!

- Do not lower subframe any further than specified.

- When lowering, make sure not to damage any components.

- Lower subframe -1- approx. 35 mm.

Installing

Install in reverse order of removal, observing the following:

Vehicles with intermediate plates on front mountings on subframe

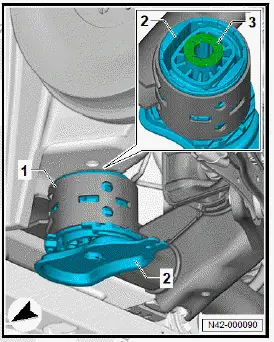

- Check if intermediate plate -1- is fitted between body and mounting.

Important

- There may be no intermediate plates -1- fitted on front subframe mounting -4- (fluted surface -3-).

- Renew intermediate plate -3-.

Important

- Intermediate plates -3- must be fitted on both sides of vehicle.

- Insert intermediate plates -3- with locking lugs into front subframe mounting -2-

All vehicles (continued)

Tightening torques

- ⇒ Rep. gr. 42 ; Assembly overview - subframe

Lowering rear axle, rear section

Special tools and workshop equipment required

- engine and gearbox jack - VAS 6931-

- gearbox support - T10337-

- Remove rear underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing rear underbody cladding .

- Unscrew bolts -3- and -4- for anti-roll bar -2- on subframe -1-. Hold anti-roll bar when doing this.

- Detach anti-roll bar from subframe, and swing it downwards.

- Unscrew bolt -2- from subframe mounting on rear right -5-.

- Lay aside bracket -1- with electrical wire -3-.

- Unscrew bolt -2- from subframe mounting on rear left -5-.

- Lay aside bracket -1- with electrical wire -3-.

- Fit gearbox support - T10337- -A- onto engine and gearbox jack - VAS 6931- -B-.

- Position gearbox support - T10337- -A- on subframe -1-.

- Support subframe -1- with engine and gearbox jack - VAS 6931- -B-.

- Unscrew bolts -2-.

NOTICE

Risk of damage to electrical wires, hoses and connections!

- Do not lower subframe any further than specified.

- When lowering, make sure not to damage any components.

- Lower subframe -1- by 35 mm.

Installing

Install in reverse order of removal, observing the following:

Tightening torques

- ⇒ Rep. gr. 42 ; Assembly overview - subframe

Securing vehicle to support arms of lifting platform

Special tools and workshop equipment required

- tensioning strap - T10523-

Removal and installation are described for the left side of vehicle as an example.

Securing for work on suspension links:

- Remove rear centre underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing rear centre underbody cladding .

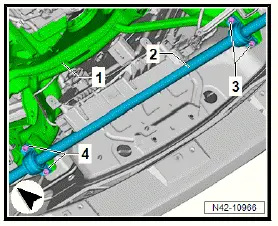

- Wrap tensioning strap - T10523- -A- support arms of lifting platform -B- on both sides of vehicle.

NOTICE

Risk of damage to lines.

- Make sure that no brake lines, electrical wires, hoses or connections are trapped or put under tension.

- Lay tensioning strap - T10523- -A- around rear axle -1-.

- Insert end of tensioning strap into ratchet of tensioning strap - T10523- -A-.

- Tension the tensioning strap - T10523- -A-.

All vehicles (continued)

Securing for work on rear axle and to remove rear axle:

- Join three tensioning straps - T10523- to each other.

NOTICE

Risk of damage to the vehicle if protective measures are insufficient.

- Cover paintwork and components using suitable workshop materials to protect them against damage.

- Make sure that no brake lines, electrical wires, hoses and connections are damaged when routing the tensioning straps.

- Position ratchets of tensioning strap so that they do not cause damage and can be actuated.

- Open rear doors on both sides of vehicle.

- Route tensioning strap - T10523- -1- through vehicle and around lifting platform.

- Wrap tensioning strap - T10523- -1- around support arms -2- of lifting platform on both sides of vehicle.

- Route tensioning strap - T10523- -1- beneath vehicle.

- Insert end of tensioning strap into ratchet of tensioning strap - T10523- -1-.

- Tension the tensioning strap - T10523- -1-.

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Rear axle

- Overview of fitting locations - rear axle

- Removing and installing rear axle

- Lowering rear axle

- Securing vehicle to support arms of lifting platform

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image