Volkswagen ID.4: Wheel alignment

- Notes on wheel alignment

- Adjusting camber at front wheels

- Adjusting toe setting at rear wheels

- Checking full steering lock

Notes on wheel alignment

Wheel alignment must always be performed using wheel alignment equipment approved for the relevant brand.

All information required for wheel alignment is provided by the wheel alignment computer.

Vehicles pulling to one side; accident vehicles

This may be due to the rack not being positioned exactly in the centre of the steering rack unit when driving in a straight line.

This is enough to result in slight steering assistance in one direction, which causes the vehicle to pull to the left or right.

Test requirements

A wheel alignment platform and wheel alignment units which have been tested and correctly adjusted are basic requirements.

Suspension, wheel bearings and steering must have been checked for excessive play and damage.

Tread depth difference must be no more than 2 mm on one axle.

Tyres inflated to correct pressures.

Vehicle must be at unladen weight.

Spare wheel must be in specified location in vehicle.

Tool kit must be in specified location in vehicle.

Sliding plates and turntables must not be touching the end stop during the alignment procedure.

Alignment unit must be properly attached and adjusted; refer to operating instructions of equipment manufacturer.

Initial instruction must have been provided by manufacturer of wheel alignment unit.

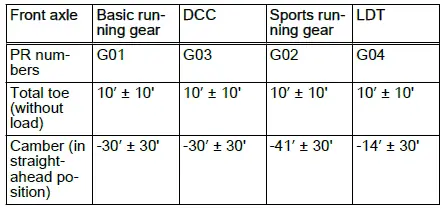

Wheel alignment specifications

Camber is not adjustable on front axle. Only minor corrections can be achieved by shifting subframe.

Toe-out on turns can also be displayed as a negative value on the wheel alignment computer, depending on the manufacturer.

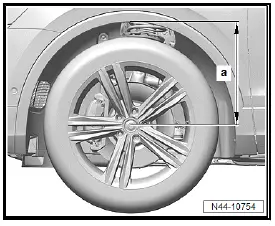

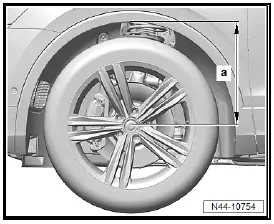

Measuring ride height

- Ride height is defined by dimension -a- between centre of wheel hub and lower edge of wheel housing.

Setting vehicle to initial position for wheel alignment

If ride height is not as specified ⇒ Rep. gr. 44 ; Specifications for wheel alignment :

- Front axle: balance out ride height by adding weights to respective suspension turret.

- Rear axle: balance out ride height by placing weights in luggage compartment at respective side.

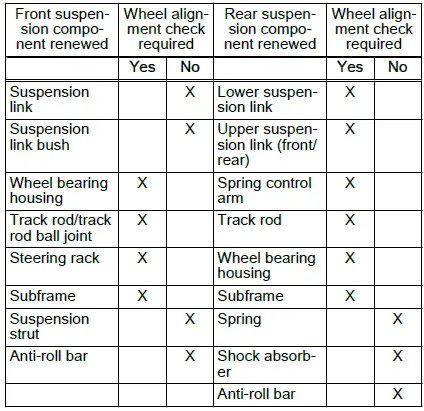

When does wheel alignment have to be checked?

Wheel alignment must be checked:

- If there are problems with handling caused by the running gear

- If the vehicle has been involved in an accident or components have been renewed

- If suspension components have been removed or renewed

- If tyres are worn unevenly.

Components renewed

All vehicles (continued)

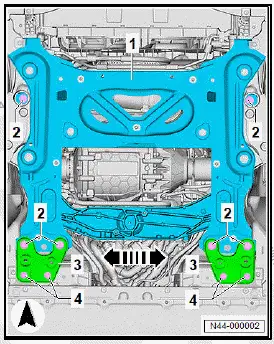

Adjusting camber at front wheels

Front axle camber cannot be adjusted; it can only be corrected slightly by moving the subframe.

The subframe may be moved to the left or right, but NOT forwards or backwards in a longitudinal direction.

- Remove underbody trim (front) ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody trim; Removing and installing underbody trim (front) .

- Remove bolts -2- one by one and screw in new bolts loosely.

- Only remove next bolt -2- after replacing previously removed bolt with a new bolt -2-.

The camber adjustment range is limited by the tolerances of the holes in the subframe -1-. If the specified value is not obtained by moving the subframe -1-, the subframe and the body must be inspected.

- Camber can now be adjusted to specification by moving subframe -1-.

- Move subframe -1- sideways until camber is the same on both sides ⇒ Rep. gr. 44 ; Wheel alignment specifications .

- Tighten bolts -2-.

Tightening torques

- ⇒ Rep. gr. 40 ; Exploded view - subframe

- ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody trim; Exploded view - underbody trim

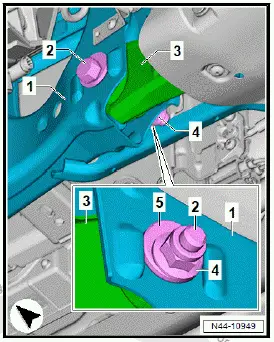

Adjusting camber at rear wheels

- Loosen nut -4- on inside of spring control arm -3-.

- Adjust camber by turning eccentric bolt -2-.

Note

Maximum adjustment range is 90º to left or right of centre position.

- Tighten new nut -4-, counterholding at eccentric bolt -2-.

- Check camber meets specification ⇒ Rep. gr. 44 ; Wheel alignment specifications .

Tightening torques

- ⇒ Rep. gr. 42 ; Exploded view - spring control arm

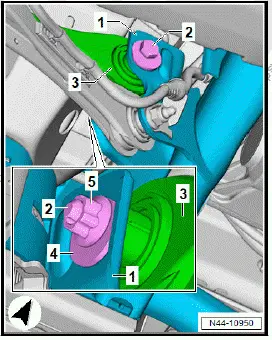

Adjusting toe setting at rear wheels

- Loosen nut -5- on inside of track rod -3-.

- Adjust toe setting by turning eccentric bolt -2-.

Note

The maximum adjustment range is 90º to the left or right of the centre position.

- Tighten new nut -5-, counterholding at eccentric bolt -2-.

- Check toe setting meets specification ⇒ Rep. gr. 44 ; Wheel alignment specifications .

Tightening torques

- ⇒ Rep. gr. 42 ; Exploded view - track rod

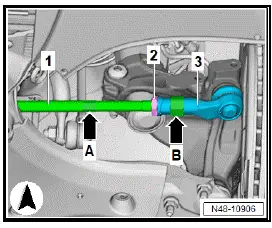

Adjusting toe setting at front wheels

- Loosen nut -2- (counterhold at hexagon flats -arrow A- on track rod -1-).

- Loosen track rod -1- at track rod ball joint -3-. To do so, apply suitable tool at hexagon flats -arrow A- and -arrow B-.

- Adjust toe setting at left and right wheels by turning hexagon flats -arrow A-. When doing this, counterhold at hexagon flats -arrow B-.

NOTICE

Risk of damage to boots if they are twisted.

- Make sure boot on steering rack is not damaged or twisted.

Twisted rubber boots wear out quickly.

- Only tighten lock nut for threaded piece with vehicle standing on the ground.

- Tighten lock nut -2-.

- Check toe setting meets specification ⇒ Rep. gr. 44 ; Wheel alignment specifications .

Tightening torques

- ⇒ Rep. gr. 48 ; Exploded view - track rods

Checking full steering lock

The wheel alignment unit is used to determine the full steering lock.

If the value for the full steering lock is outside the permitted tolerances or the steering wheel is not straight, observe the following procedure:

- Check steering and suspension components for damage and deformation.

- Check symmetry of track rods.

- Renew any damaged components.

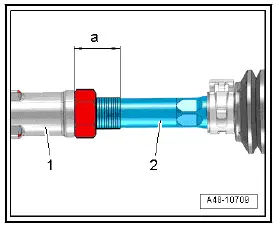

- Measure dimension -a- on both track rod ball joints. Adjust track rod ball joints to same dimension.

Important

- Dimension -a- must be the same on left and right track rod ball joint.

- Maximum permitted tolerance between left and right is < 2.5 mm.

- When returning steering to centre position, allow steering wheel to settle by rocking it evenly back and forth past centre position a few times.

Preparations for testing

- Proper toe setting is not possible without wheel runout compensation.

- Any existing lateral runout of the wheels must be compensated for, otherwise the result will be falsified.

- The specified toe-in tolerance may already be exceeded by the permitted amount of axial runout at the wheel rims. In such cases it is not possible to set the toe-in correctly without first compensating for the wheel runout.

- Observe the instructions from the manufacturer of the wheel alignment equipment.

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Wheel alignment

- Notes on wheel alignment

- Adjusting camber at front wheels

- Adjusting toe setting at rear wheels

- Checking full steering lock

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image