Volkswagen ID.4: Luggage compartment floor

- Assembly overview - sealing channel support

- Assembly overview - centre luggage compartment floor

- Assembly overview - luggage compartment floor cross member

- Renewing floor panel reinforcement

- Renewing centre luggage compartment floor

- Renewing rear luggage compartment floor

- Renewing luggage compartment floor cross member

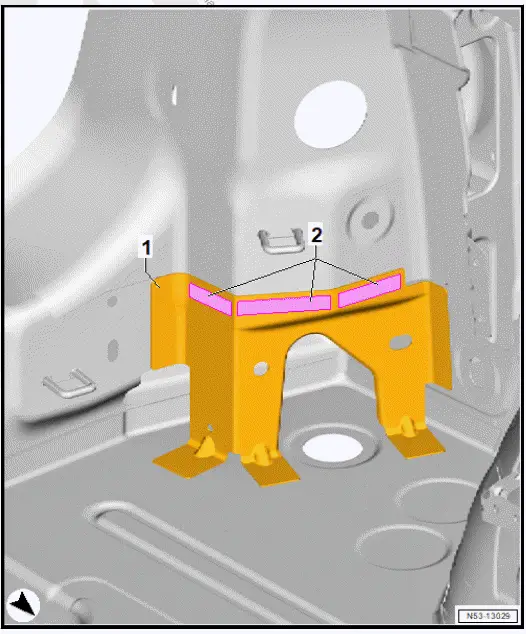

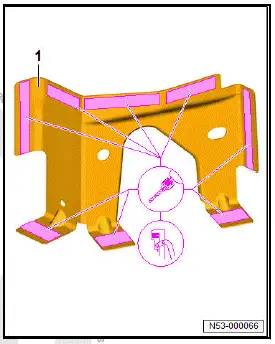

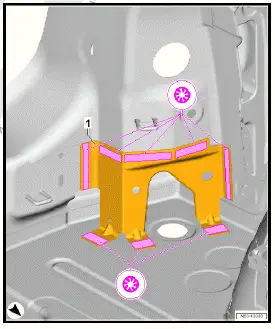

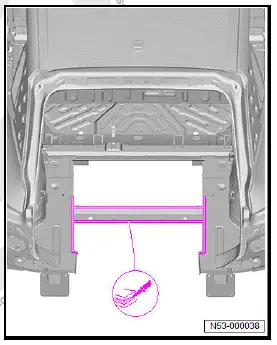

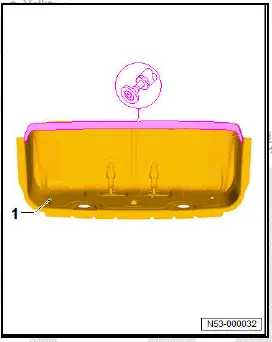

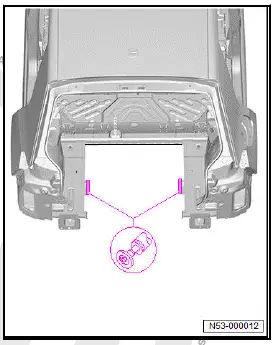

Assembly overview - sealing channel support

Overview shown for left side of vehicle as an example

- Support

- Sealing channel

- ⇒ Rep. gr. 53; Renewing sealing channel support

- Bonded areas

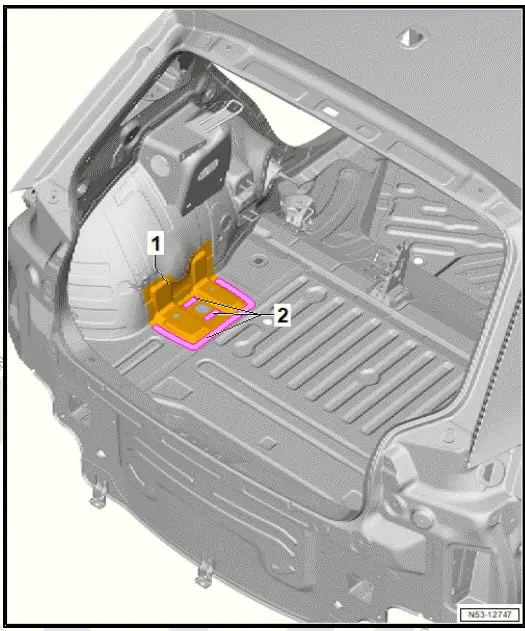

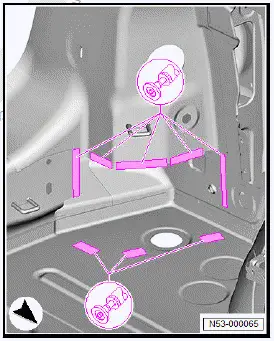

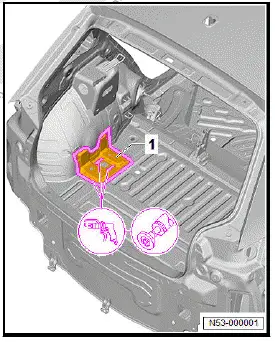

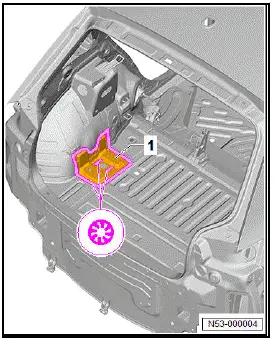

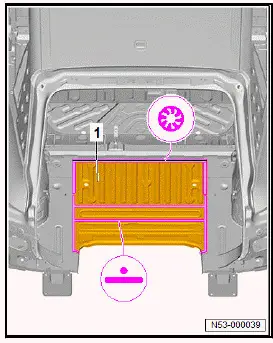

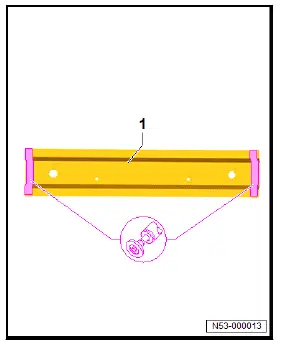

Assembly overview - floor panel reinforcement

Overview shown for left side of vehicle as an example

- Floor panel reinforcement

- ⇒ Rep. gr. 53; Renewing floor panel reinforcement

- Bonded areas

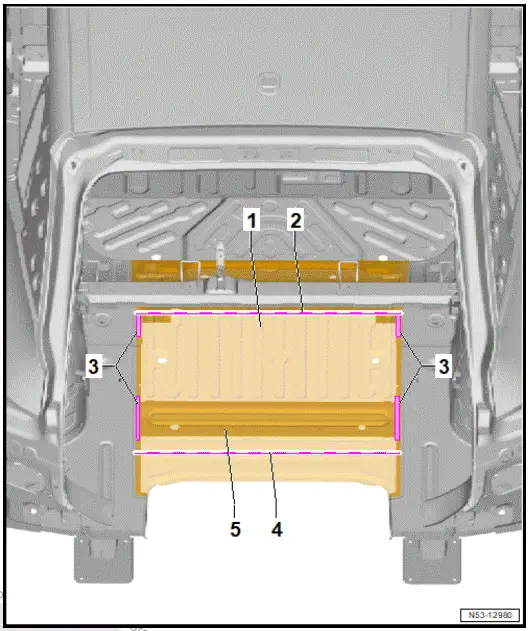

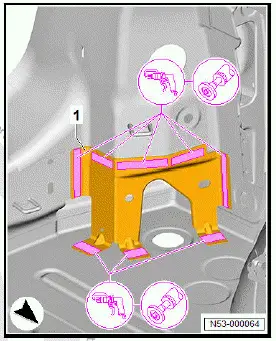

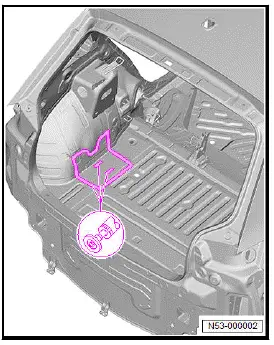

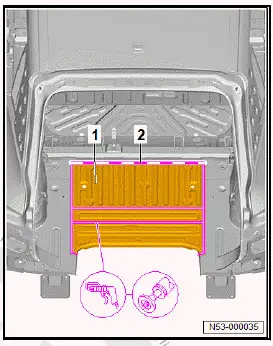

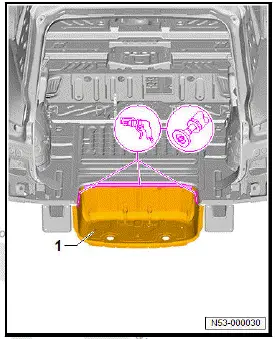

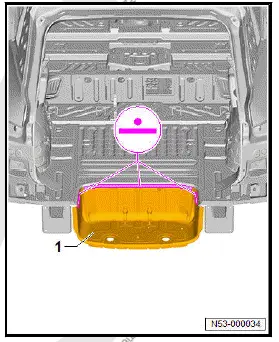

Assembly overview - centre luggage compartment floor

- Centre luggage compartment floor

- ⇒ Rep. gr. 53; Renewing centre luggage compartment floor

- Separating cut

- Bonded area

- Separating cut

- Rear floor cross member

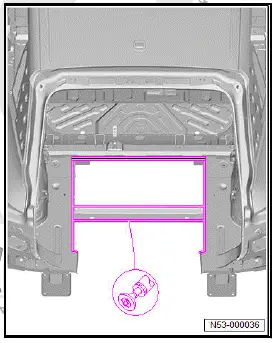

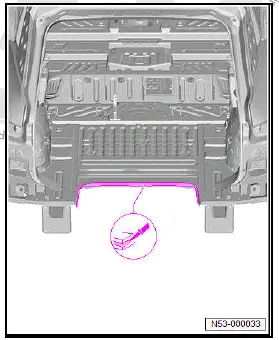

Assembly overview - rear luggage compartment floor

- Rear luggage compartment floor

- ⇒ Rep. gr. 53; Renewing rear luggage compartment floor

- Bonded area

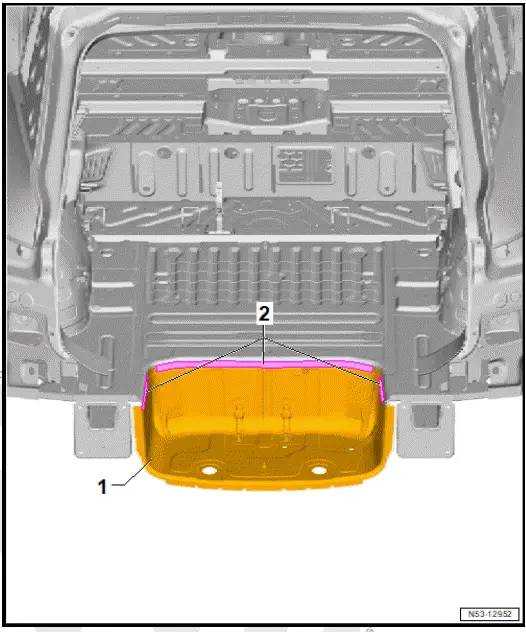

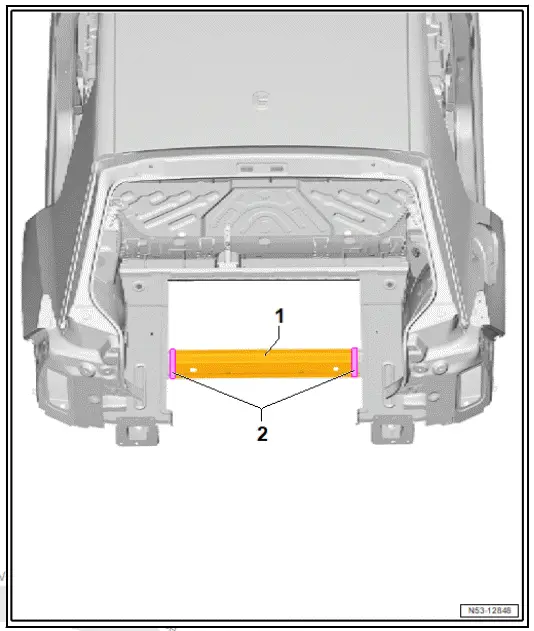

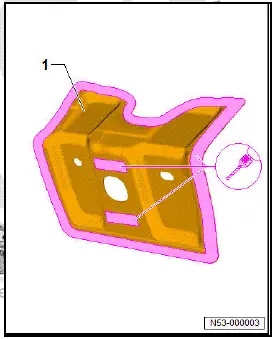

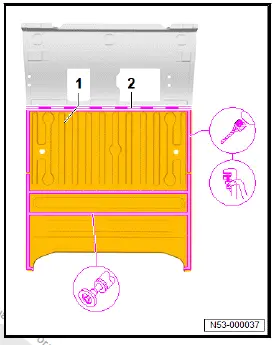

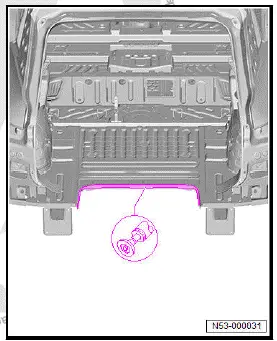

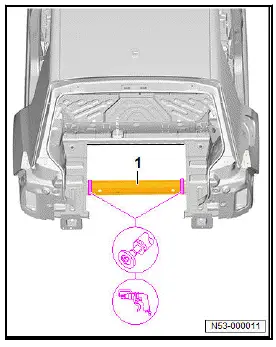

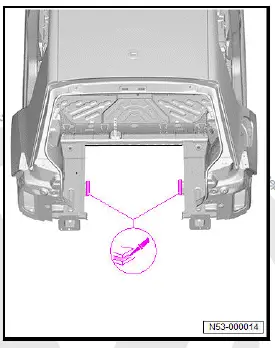

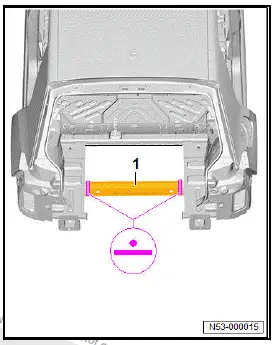

Assembly overview - luggage compartment floor cross member

- Luggage compartment floor cross member

- ⇒ Rep. gr. 53; Renewing luggage compartment floor cross member

- Bonded area

Renewing sealing channel support

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

Observe safety information ⇒ Rep. gr. 00; Safety information

Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

Removal and installation are described for left side of vehicle as an example.

Removing

- Separate original joint.

- Detach sealing channel support -1-.

- Remove remaining material.

- Completely remove remaining adhesive.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

Installing

- Drill or alternately punch 8 mm holes for SG plug weld seam in new part -1-.

- Adapt new part -1- to fit and fix in position.

- Check fit with add-on parts.

- Weld in new part -1-, SG plug weld seam.

Renewing floor panel reinforcement

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

Observe safety information ⇒ Rep. gr. 00; Safety information Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

Removal and installation are described for left side of vehicle as an example.

Removing

- Separate original joint.

- Remove floor panel reinforcement -1-.

- Remove remaining material.

- Completely remove remaining adhesive.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

Installing

- Drill 8 mm diameter holes for SG plug weld seam in new part -1-.

- Adapt new part -1- to fit and fix in position.

- Check fit with add-on parts.

- Weld in new part -1-, SG plug weld seam.

Renewing centre luggage compartment floor

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

NOTICE

If welds are positioned too far on outside, strength could be impaired

- RP weld points must be placed as far as possible from outer edge of welding flange.

NOTICE

If adhesive is applied prematurely, bond could be impaired

- New part must be welded in within 90 minutes.

Observe safety information ⇒ Rep. gr. 00; Safety information Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

Removing

Rear luggage compartment floor removed ⇒ Rep. gr. 53; Renewing rear luggage compartment floor.

Floor panel reinforcement removed ⇒ Rep. gr. 53; Renewing floor panel reinforcement.

- Make separating cut -2- in a straight line.

- Separate original joint.

- Remove centre luggage compartment floor -1-.

- Remove remaining material.

- Completely remove remaining adhesive.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

Installing

- For allocation of 2-pack body adhesive, see ⇒ Electronic parts catalogue (ETKA)

Important

- New parts must be adapted and attached with the vehicle standing on its wheels or straightening bracket set.

- Transfer separating cut -2- to new part -1-, and cut in a straight line.

- Drill or alternately punch 8 mm holes for SG plug weld seam in new part -1-.

- Grind welding surfaces and bonding surfaces on new part -1- down to bare metal and clean.

- Apply 2-component body adhesive to entire surface.

- Adapt new part -1- to fit and fix in position.

- Weld in new part -1-, SG plug weld seam and RP spot weld seam.

- Install rear luggage compartment floor ⇒ Rep. gr. 53; Renewing rear luggage compartment floor.

- Install floor panel reinforcement ⇒ Rep. gr. 53; Renewing floor panel reinforcement.

Renewing rear luggage compartment floor

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

NOTICE

If welds are positioned too far on outside, strength could be impaired

- RP weld points must be placed as far as possible from outer edge of welding flange.

NOTICE

If adhesive is applied prematurely, bond could be impaired

- New part must be welded in within 90 minutes.

Observe safety information ⇒ Rep. gr. 00; Safety information Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

Removing

Rear cross panel removed ⇒ Rep. gr. 53; Renewing rear cross panel.

- Separate original joint.

- Remove rear floor panel -1-.

- Remove remaining material.

- Completely remove remaining adhesive.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

Installing

- For allocation of 2-pack body adhesive, see ⇒ Electronic parts catalogue (ETKA)

Important

- New parts must be adapted and attached with the vehicle standing on its wheels or straightening bracket set.

- Grind welding surfaces and bonding surfaces on new part -1- down to bare metal and clean.

- Apply 2-component body adhesive to entire surface.

- Adapt new part -1- to fit and fix in position.

- Weld in new part -1-, RP spot weld seam.

- Install rear cross panel ⇒ Rep. gr. 53; Renewing rear cross panel.

Renewing luggage compartment floor cross member

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

NOTICE

If welds are positioned too far on outside, strength could be impaired

- RP weld points must be placed as far as possible from outer edge of welding flange.

NOTICE

If adhesive is applied prematurely, bond could be impaired

- New part must be welded in within 90 minutes.

Observe safety information ⇒ Rep. gr. 00; Safety information Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

Removing

Centre luggage compartment floor part section removed ⇒ Rep.

gr. 53; Renewing centre luggage compartment floor.

- Separate original joint.

- Remove luggage compartment floor cross member -1-.

- Remove remaining material.

- Completely remove remaining adhesive.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

Installing

- For allocation of 2-pack body adhesive, see ⇒ Electronic parts catalogue (ETKA)

Important

- New parts must be adapted and attached with the vehicle standing on its wheels or straightening bracket set.

- Grind welding surfaces and bonding surfaces on new part -1- down to bare metal and clean.

- Apply 2-component body adhesive to entire surface.

- Adapt new part -1- to fit and fix in position

- Check fit with add-on parts.

- Weld in new part -1-, RP spot weld seam.

- Install centre luggage compartment floor part section ⇒ Rep.

gr. 53; Renewing centre luggage compartment floor.

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Luggage compartment floor

- Assembly overview - sealing channel support

- Assembly overview - centre luggage compartment floor

- Assembly overview - luggage compartment floor cross member

- Renewing floor panel reinforcement

- Renewing centre luggage compartment floor

- Renewing rear luggage compartment floor

- Renewing luggage compartment floor cross member

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image