Volkswagen ID.4: Rear wheel housing

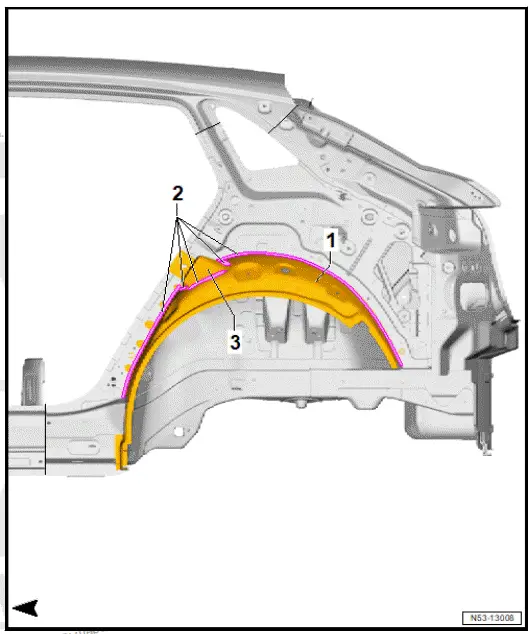

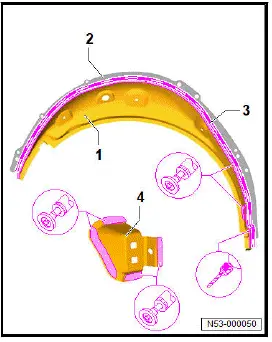

Assembly overview - rear wheel housing

Overview shown for left side of vehicle as an example

- Outer wheel housing

- ⇒ Rep. gr. 53; Renewing rear wheel housing

- Bonded area

- Lock reinforcement

- Renew after removing

Renewing rear wheel housing

WARNING

Gases/vapours hazardous to health are generated when welding, soldering or cutting using tools which produce sparks in foam-treated areas.

- Do not weld, solder or cut closer than 15 mm to moulded foam inserts.

- Use an extraction system during work.

NOTICE

If separating cuts are made too deep, underlying reinforcement could be damaged.

- Only make separating cuts with body saw.

- Rewelding of reinforcements is not permitted due to safety reasons.

NOTICE

If welds are positioned too far on outside, strength could be impaired

- RP weld points must be placed as far as possible from outer edge of welding flange.

NOTICE

If adhesive is applied prematurely, bond could be impaired

- New part must be welded in within 90 minutes.

Observe safety information ⇒ Rep. gr. 00; Safety information Only tools and workshop equipment authorised by Volkswagen AG may be used ⇒ 2.1

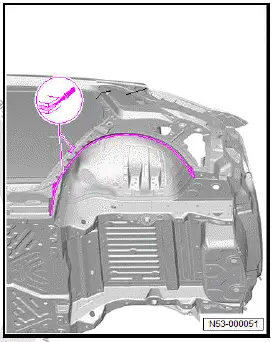

Removal and installation are described for left side of vehicle as an example.

Removing

Side panel removed ⇒ Rep. gr. 53; Renewing side panel, part section.

- Separate original joint.

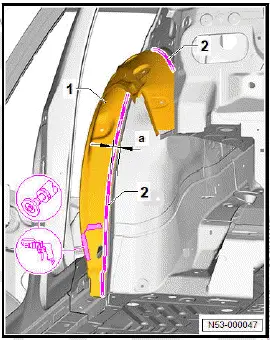

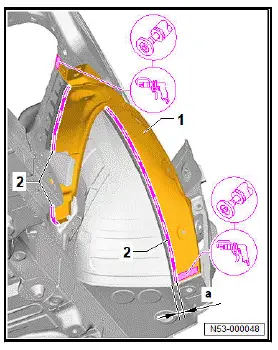

- Mark parting cut -2- all around on outer wheel housing -1- according to dimension -a- and cut in a straight line.

- Dimension -a- = 20 mm

- Separate original joint.

- Mark parting cut -2- all around on outer wheel housing -1- according to dimension -a- and cut in a straight line.

- Dimension -a- = 20 mm

- Completely remove remaining adhesive.

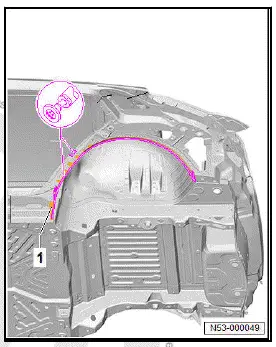

- Sand bonding surfaces and welding surfaces on remaining material -1- down to bare metal.

- Grind bonding surfaces and welding surfaces back to bare metal and clean.

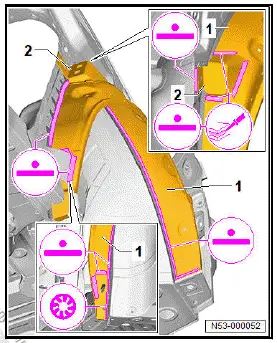

Installing

For allocation of 2-pack body adhesive, see ⇒ Electronic parts catalogue (ETKA)

Important

- New parts must be adapted and attached with the vehicle standing on the straightening bracket set.

- Transfer parting cut -3- to new part -- and cut.

- Remove remaining part -2-.

- Drill 8 mm diameter holes for SG plug weld seam.

- Grind bonding surfaces and welding surfaces on new part

- -1- and -4- down to bare metal and clean.

- Apply 2-component body adhesive to entire surface.

- Adapt new part -1- to fit and fix in position.

- Check fit with add-on parts.

- Weld in new part -1-, SG plug weld seam and RP spot weld seam.

- Apply 2-component body adhesive to entire surface.

- Adapt new part -2- to fit and fix in position.

- Check fit with add-on parts.

- Weld in new part -2-, RP spot weld seam.

- Install side panel ⇒ Rep. gr. 53; Renewing side panel, part section.

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image