Volkswagen ID.4: Removing and installing front motor

- Assembly overview - front motor

- Removing front motor

- Securing motor to engine and gearbox support, front motor

- Installing front motor

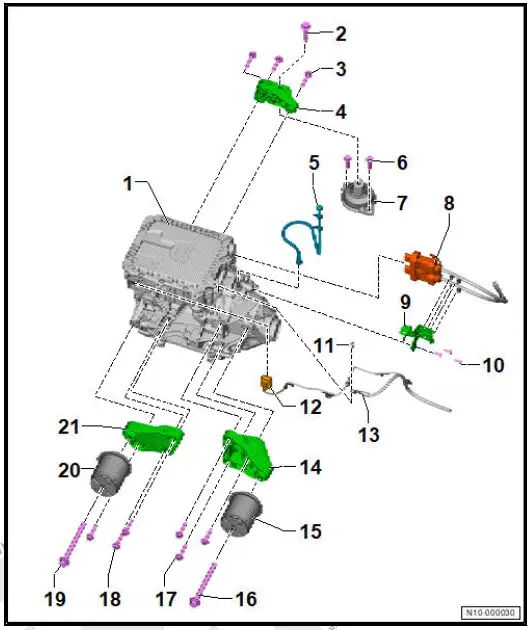

Assembly overview - front motor

Assembly overview - front motor, left-hand drive vehicles

- hree-phase current drive 2 - VX97-

- With electric drive motor

- V717-

- With drive motor 2 temperature sender - G1146-

- With drive motor 2 rotor position sender 1 - G1147-

- With power and control electronics 2 for electric drive - JX4-

- ⇒ Rep. gr. 93 ; Removing and installing power and control electronics for electric drive

- ⇒ Rep. gr. 10 ; Removing front motor

- ⇒ Rep. gr. 10 ; Installing front motor

- Bolt for gearbox mounting

- Renew after removing

- 70 Nm +90º

- Bolt for gearbox support

- Qty. 3

- Renew after removing

- 50 Nm +90º

- Gearbox support

- Gearbox breather line

- Bolt for gearbox mounting

- Qty. 2

- Renew after removing

- 50 Nm +90º

- Gearbox mounting

- ⇒ Rep. gr. 10 ; Removing and installing gearbox mounting

- High-voltage connector for power and control electronics 2 for electric drive - JX4-

- High-voltage cable duct

- Bolt for cable guide

- Qty. 3

- 8 Nm

- Bolt for potential equalisation line

- 8 Nm

- Electrical connector for power and control electronics 2 for electric drive - JX4-

- Potential equalisation line

- Engine support

- Front motor mounting

- ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Renewing front motor mounting

- Bolt for motor mounting

- Renew after removing

- 130 Nm +180º

- Bolt for motor support

- Qty. 3

- Renew after removing

- 50 Nm +90º

- Bolt for motor support

- Qty. 3

- Renew after removing

- 50 Nm +90º

- Bolt for motor mounting

- Renew after removing

- 130 Nm +180º

- Front motor mounting

- ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Renewing front motor mounting

- Engine support

Assembly overview - noise insulation, motor

- Retaining clip

- Clip/bolt

- Depending on equipment/version

- Bolt with washer

- Qty. 2

- 5 Nm

- Clip

- Qty. 2

- Three-phase current drive 2 - VX97-

- Noise insulation

- Depending on equipment/version

- Retaining clip

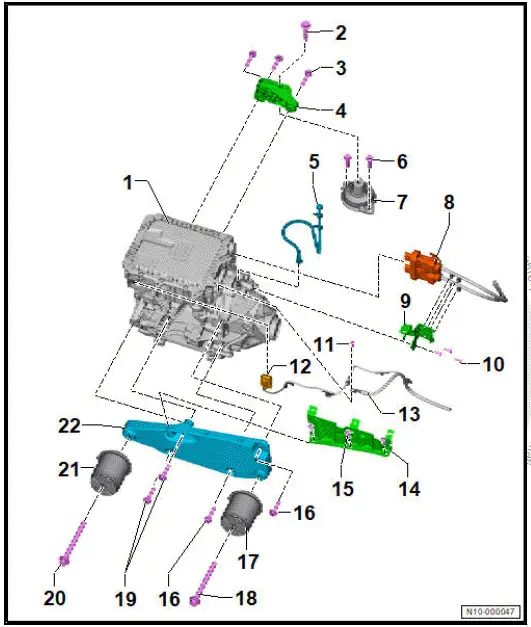

Assembly overview - front motor, right-hand drive vehicles

- Three-phase current drive 2 - VX97-

- With electric drive motor

- V717-

- With drive motor 2 temperature sender - G1146-

- With drive motor 2 rotor position sender 1 - G1147-

- With power and control electronics 2 for electric drive - JX4-

- ⇒ Rep. gr. 93 ; Removing and installing power and control electronics for electric drive

- ⇒ Rep. gr. 10 ; Removing front motor

- ⇒ Rep. gr. 10 ; Installing front motor

- Bolt for gearbox mounting

- Renew after removing

- 70 Nm +90º

- Bolt for gearbox support

- Qty. 3

- Renew after removing

- 50 Nm +90º

- Gearbox support

- Gearbox breather line

- Bolt for gearbox mounting

- Qty. 2

- Renew after removing

- 50 Nm +90º

- Gearbox mounting

- ⇒ Rep. gr. 10 ; Removing and installing gearbox mounting

- High-voltage connector for power and control electronics 2 for electric drive - JX4-

- High-voltage cable duct

- Bolt for cable guide

- Qty. 3

- 8 Nm

- Bolt for potential equalisation line

- 8 Nm

- Electrical connector for power and control electronics 2 for electric drive - JX4-

- Potential equalisation line

- Cover plate

- Bolt

- Qty. 3

- 8 Nm

- Bolt for motor support

- Qty. 2

- Renew after removing

- 50 Nm +90º

- Front motor mounting

- ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Renewing front motor mounting

- Bolt for front motor mounting

- Renew after removing

- 130 Nm +180º

- Bolt for motor support

- Qty. 2

- Renew after removing

- 50 Nm +90º

- Bolt for front motor mounting

- Renew after removing

- 130 Nm +180º

- Front motor mounting

- ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Renewing front motor mounting

- Engine support

Assembly overview - noise insulation, motor

- Retaining clip

- Clip/bolt

- Depending on equipment/version

- Bolt with washer

- Qty. 2

- 5 Nm

- Clip

- Qty. 2

- Three-phase current drive 2 - VX97-

- Noise insulation

- Depending on equipment/version

- Retaining clip

Removing front motor

Removing front motor, left-hand drive vehicles

Special tools and workshop equipment required

- engine bung set - VAS 6122-

- lifting tackle - VAS 501 021-

- workshop hoist - VAS 6100-

Three-phase current drive 2 - VX97- with power and control electronics 2 for electric drive - JX4- will henceforth be referred to as "motor".

Removing

Important

- Once the drive shafts have been removed, the drive shaft flange must be sealed with a suitable plug from engine bung set - VAS 6122- .

- Make sure that no gear oil leaks out.

- Remove subframe together with motor ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Removing and installing subframe with motor .

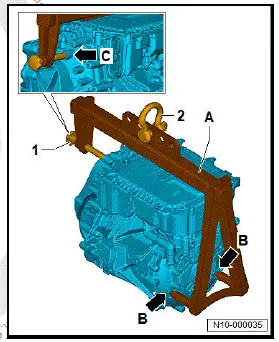

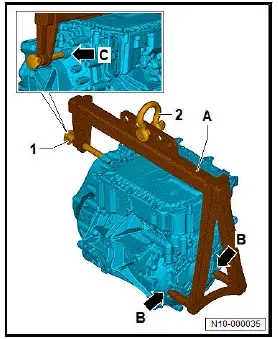

- Insert bracket -A- of lifting tackle - VAS 501 021- into holes -arrows B-.

- Screw bolt -1- to stop into hole -arrow C-.

- Secure shackle -2- in centre hole.

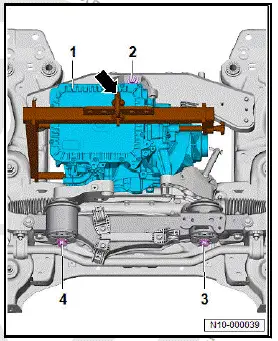

- Attach workshop hoist - VAS 6100- to shackle -arrow-.

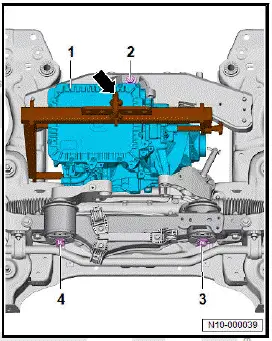

- Use workshop hoist to take up weight of motor -1-.

- Unscrew bolts -2-, -3- and -4-.

- Use workshop hoist to raise motor -1-.

- For further repairs, ⇒ Rep. gr. 10 ; Secure motor to engine and gearbox support, front motor .

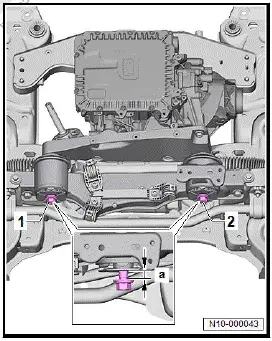

Removing front motor, right-hand drive vehicles

Special tools and workshop equipment required

- engine bung set - VAS 6122-

- lifting tackle - VAS 501 021-

- workshop hoist - VAS 6100

Three-phase current drive 2 - VX97- with power and control electronics 2 for electric drive - JX4- will henceforth be referred to as "motor".

Removing

Important

- Once the drive shafts have been removed, the drive shaft flange must be sealed with a suitable plug from engine bung set - VAS 6122- .

- Make sure that no gear oil leaks out.

- Remove subframe together with motor ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Removing and installing subframe with motor .

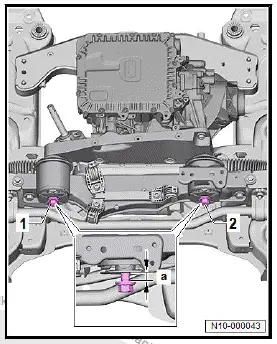

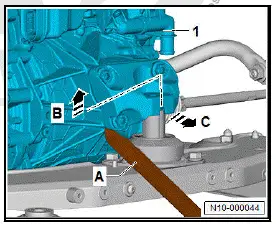

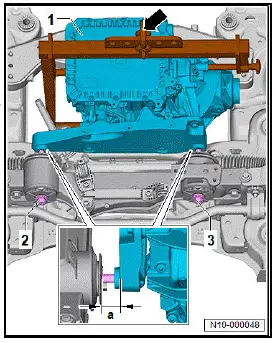

- Loosen bolts -1- and -2-, and unscrew them by 20 mm -a-.

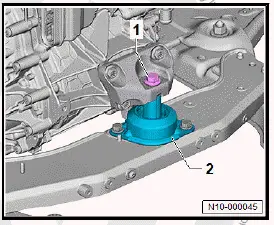

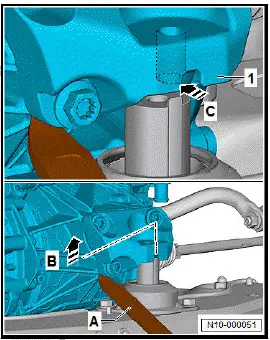

- Unscrew bolt -1- for motor mounting -2-.

- Raise motor -1- 10 mm in direction of -arrow B- using assembly lever -A-, and pull it towards rear in direction of -arrow C-.

- Insert bracket -A- of lifting tackle - VAS 501 021- into holes -arrows B-.

- Screw bolt -1- to stop into hole -arrow C-.

- Secure shackle -2- in centre hole.

- Attach workshop hoist - VAS 6100- to shackle -arrow-.

- Use workshop hoist to take up weight of motor -1-.

- Unscrew bolts -2- and -3-.

- Use workshop hoist to raise motor -1-.

- For further repairs, ⇒ Rep. gr. 10 ; Secure motor to engine and gearbox support, front motor .

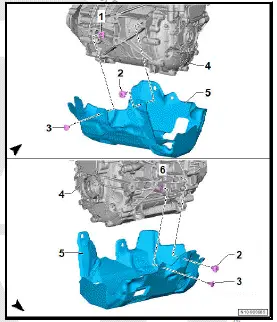

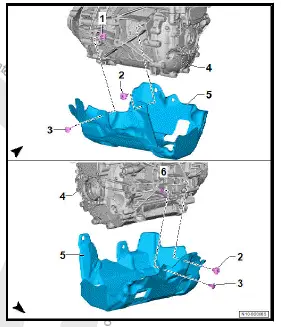

Securing motor to engine and gearbox support, front motor

Special tools and workshop equipment required

- Motor bracket - VAS 6095A/1-22-

- engine and gearbox jack - VAS 6095A-

- lifting tackle - VAS 501 021-

- retaining plate - VW309A-

- workshop hoist - VAS 6100-

The three-phase current drive 2 - VX97- along with the power and control electronics 2 for electric drive - JX4- will henceforth be referred to as "motor".

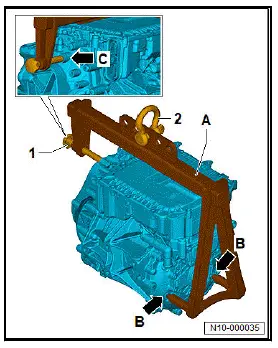

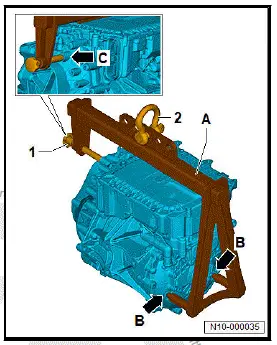

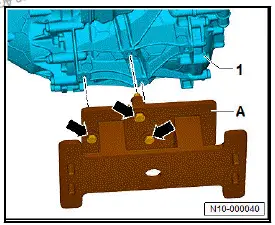

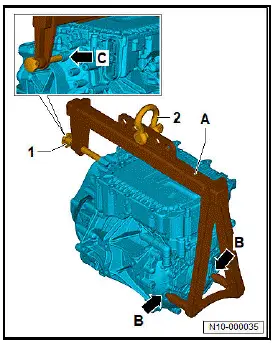

- Insert bracket of lifting tackle - VAS 501 021- -A- into holes -arrows B-.

- Screw bolt -1- to stop into hole -arrow C- by hand.

- Secure shackle -2- in centre hole.

- Attach workshop hoist - VAS 6100- to shackle -2-, and raise motor.

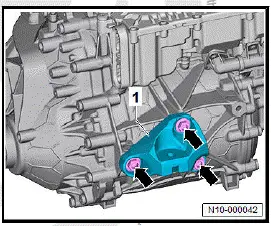

- Unscrew and remove bolts -arrows- and remove motor support -1-.

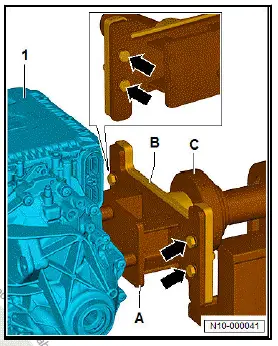

- Mount motor bracket - VAS 6095A/1-22- -A- on motor -1- and tighten bolts -arrows-.

- Insert retaining plate - VW309A- -B- into engine and gearbox jack - VAS 6095A- -C-.

- Mount motor bracket - VAS 6095A/1-22- -A- on retaining plate - VW309A- -B- and tighten bolts -arrows-.

Installing front motor

Installing front motor, left-hand drive vehicles

Special tools and workshop equipment required

- lifting tackle - VAS 501 021-

- workshop hoist - VAS 6100-

Three-phase current drive 2 - VX97- with power and control electronics 2 for electric drive - JX4- will henceforth be referred to as "motor".

Installing

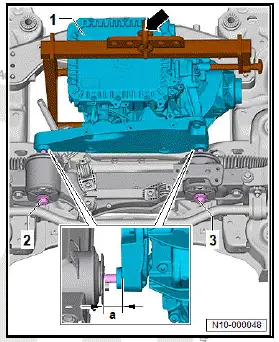

- Insert bracket -A- into holes -arrows B-.

- Screw bolt -1- to stop into hole -arrow C-.

- Secure shackle -2- in centre hole.

- Attach workshop hoist - VAS 6100- to shackle -2-.

- Use workshop hoist to position motor -1- on subframe.

- Align motor support with gearbox mounting, and screw in bolts -3- and -4- until stop.

- Tighten bolt -2-.

- Tighten bolts -3- and -4-.

- Detach lifting tackle - VAS 501 021- -arrow

Further installation is carried out in reverse order of removal, observing the following:

- Install subframe together with motor ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Removing and installing subframe with motor .

Tightening torques

- ⇒ Rep. gr. 10 ; Assembly overview - front motor

Installing front motor, right-hand drive vehicles

Special tools and workshop equipment required

- lifting tackle - VAS 501 021-

- workshop hoist - VAS 6100-

Three-phase current drive 2 - VX97- with power and control electronics 2 for electric drive - JX4- will henceforth be referred to as "motor".

Installing

- Insert bracket -A- into holes -arrows B-.

- Screw bolt -1- to stop into hole -arrow C-.

- Secure shackle -2- in centre hole.

- Attach workshop hoist - VAS 6100- to shackle -2-.

- Use workshop hoist to position motor -1- on subframe in such a way that a distance of -a- = 20 mm remains between motor support and gearbox mounting.

- Align motor support and gearbox mounting with each other.

- Screw in bolts -2- and -3- until bolt heads make contact with gearbox mounting.

- Detach lifting tackle - VAS 501 021- -arrow-.

- Raise motor -1- 10 mm in direction of -arrow B- using assembly lever -A-, and pull it against gearbox mounting in direction of -arrow C-.

- Screw in bolts -1- and -2- entirely, and tighten them.

Further installation is carried out in reverse order of removal, observing the following:

- Install subframe together with motor ⇒ Running gear, axles, steering; Rep. gr. 40 ; Subframe; Removing and installing subframe with motor .

Tightening torques

- ⇒ Rep. gr. 10 ; Assembly overview - front motor

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Removing and installing front motor

- Assembly overview - front motor

- Removing front motor

- Securing motor to engine and gearbox support, front motor

- Installing front motor

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image