Volkswagen ID.4: Steering rack

- Assembly overview - steering rack, left-hand drive

- Assembly overview - steering rack, right-hand drive

- Assembly overview - track rods

- Removing and installing steering rack, all-wheel drive

- Removing and installing steering rack, rear-wheel drive

- Servicing steering rack

- Removing and installing boot

- Removing and installing track rod

- Removing and installing track rod ball joint

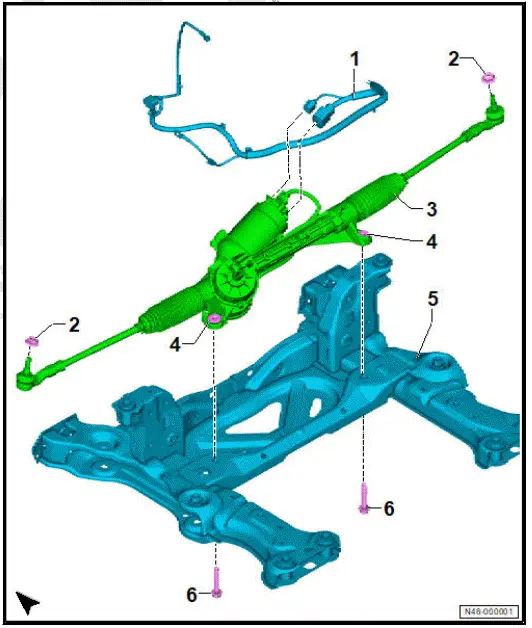

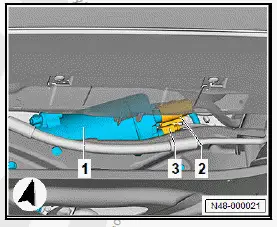

Assembly overview - steering rack, left-hand drive

- Electrical wire

- Nut

- Qty. 2

- Renew after removing

- M 12 x 1.5

- 20 Nm +90º

- Steering rack with power steering control unit - J500-

- ⇒ Rep. gr. 48 ; Assembly overview - track rods

- ⇒ Rep. gr. 48 ; Removing and installing steering rack

- Threaded bush

- Qty. 2

- ⇒ Rep. gr. 48 ; Repairing steering rack

- Subframe

- ⇒ Rep. gr. 40 ; Assembly overview - subframe

- ⇒ Rep. gr. 40 ; Fixing subframe in position

- ⇒ Rep. gr. 40 ; Removing and installing subframe with steering rack

- Bolt

- Qty. 2

- Renew after removing

- M12 × 1.5 × 70

- 70 Nm +180º

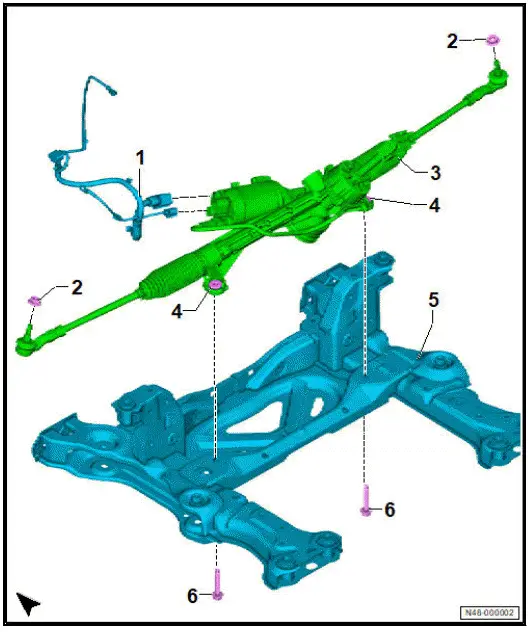

Assembly overview - steering rack, right-hand drive

- Electrical wire

- Nut

- Qty. 2

- Renew after removing

- 20 Nm +90º

- Steering rack with power steering control unit - J500-

- ⇒ Rep. gr. 48 ; Assembly overview - track rods

- ⇒ Rep. gr. 48 ; Removing and installing steering rack

- Threaded bush

- Qty. 2

- ⇒ Rep. gr. 48 ; Repairing steering rack

- Subframe

- ⇒ Rep. gr. 40 ; Assembly overview - subframe

- ⇒ Rep. gr. 40 ; Fixing subframe in position

- ⇒ Rep. gr. 40 ; Removing and installing subframe with steering rack

- Bolt

- Qty. 2

- Renew after removing

- M12 × 1.5 × 70

- 70 Nm +180º

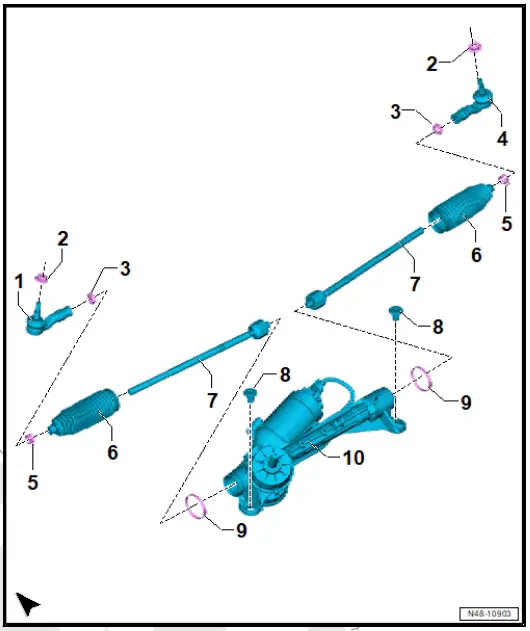

Assembly overview - track rods

- Left track rod ball joint

- ⇒ Rep. gr. 48 ; Removing and installing track rod ball joint

- Nut

- Qty. 2

- Renew after removing

- M 12 x 1.5

- 20 Nm +90º

- Nut

- Qty. 2

- M16 × 1.5

- 70 Nm

- Right track rod ball joint

- ⇒ Rep. gr. 48 ; Removing and installing track rod ball joint

- Clamp

- Qty. 2

- Renew after removing

- Boot

- Renew after removing

- ⇒ Rep. gr. 48 ; Removing and installing boot

- Track rod

- ⇒ Rep. gr. 48 ; Removing and installing track rod

- 100 Nm

- Threaded bush

- Qty. 2

- ⇒ Rep. gr. 48 ; Servicing steering rack

- Clamp

- Qty. 2

- Renew after removing

- Steering rack with power steering control unit - J500-

- ⇒ Rep. gr. 48 ; Assembly overview - steering rack

- ⇒ Rep. gr. 48 ; Removing and installing steering rack

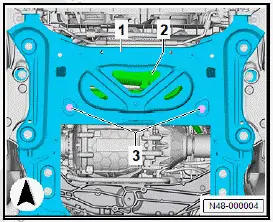

Removing and installing steering rack, all-wheel drive

Removing

Steering rack with power steering control unit - J500- will henceforth be referred to as "steering rack".

- Turn steering wheel to straight ahead position.

- Disconnect battery ⇒ Electrical system; Rep. gr. 27 ; Battery; Disconnecting and connecting battery .

- Remove front underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing front underbody cladding .

- Loosen bolts -3-.

- ⇒ Rep. gr. 10 ; Removing and installing front motor; Removing front motor

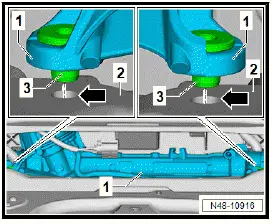

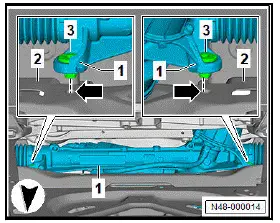

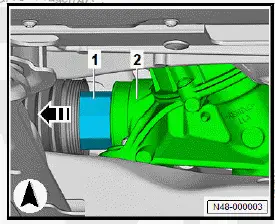

- Lever steering rack -2- with threaded bushes out of holes of subframe -1-.

- Unscrew bolts -3-.

- Remove steering rack.

Installing

Install in reverse order of removal, observing the following:

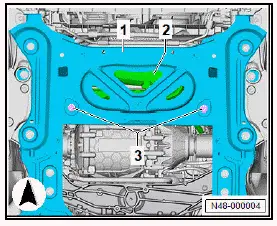

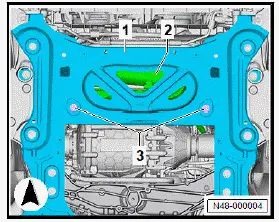

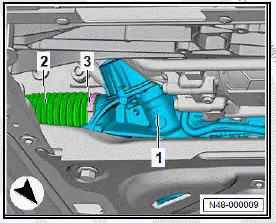

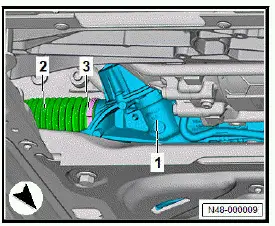

- Position steering rack -1- on subframe -2-.

Important

- Threaded bushes -3- of steering rack -1- must be inserted in holes -arrows- of subframe -2-.

- Perform basic setting for steering angle sender using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

- Adapt electromechanical power steering using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

Important

- If a new steering rack has been installed:

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - steering rack

Removing and installing steering rack, rear-wheel drive

Removing and installing steering rack, left-hand drive

Removing

Steering rack with power steering control unit - J500- will henceforth be referred to as "steering rack".

- Turn steering wheel to straight ahead position.

- Disconnect battery ⇒ Electrical system; Rep. gr. 27 ; Battery; Disconnecting and connecting battery .

- Remove front underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing front underbody cladding .

- Unscrew bolts -3-.

- Unscrew bolt -3-.

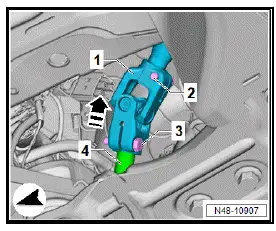

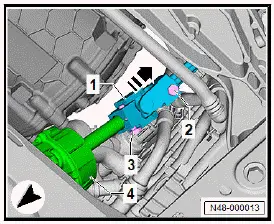

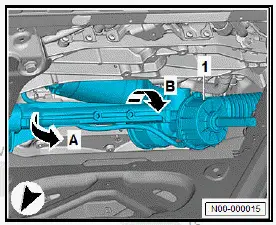

- Pull universal joint -1- in direction of -arrow- off steering rack -4-.

- Remove track rods on both sides of vehicle ⇒ Rep. gr. 48 ; Removing and installing track rod .

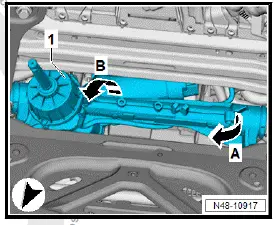

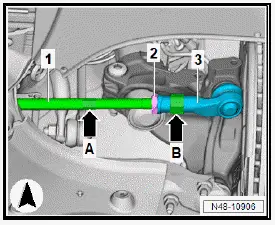

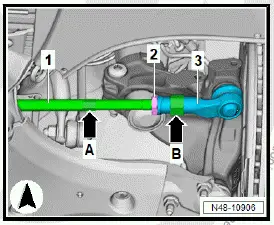

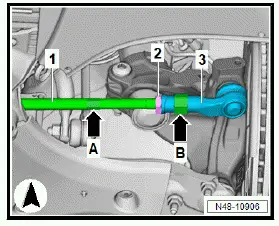

- Lever steering rack -1- with threaded bushes -3- out of holes -arrows- of subframe -2-.

- First, swing steering rack -1- on right side in direction of -arrow A-.

- Then, swing steering rack -1- in direction of -arrow B-.

- Disconnect electrical connectors -1- and -4- from steering rack -3-.

- Unclip electrical wire from steering rack.

- Remove steering rack -3- downwards.

Installing

Install in reverse order of removal, observing the following:

- Position steering rack -1- on subframe -2-.

Important

- Threaded bushes -3- of steering rack -1- must be inserted in holes -arrows- of subframe -2-.

- Perform basic setting for steering angle sender using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

- Adapt electromechanical power steering using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

Important

- If a new steering rack has been installed:

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - steering rack

Removing and installing steering rack, right-hand drive vehicle

Removing

Steering rack with power steering control unit - J500- will henceforth be referred to as "steering rack".

- Turn steering wheel to straight ahead position.

- Disconnect battery ⇒ Electrical system; Rep. gr. 27 ; Battery; Disconnecting and connecting battery .

- Remove front underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing front underbody cladding .

- Unscrew bolts -3-.

- Unscrew bolt -3-.

- Pull universal joint -1- in direction of -arrow- off steering rack -4-.

- Remove track rods on both sides of vehicle ⇒ Rep. gr. 48 ; Removing and installing track rod .

- Disconnect electrical connectors -2- and -3- from steering rack -1-.

- Unclip electrical wire from steering rack.

- Lever steering rack -1- with threaded bushes -3- out of holes -arrows- of subframe -2-.

- Swing steering rack -1- on left side in direction of -arrow A-.

- Swing steering rack -1- in direction of -arrow B-.

- Remove steering rack -1- downwards.

Installing

Install in reverse order of removal, observing the following:

- Position steering rack -1- on subframe -2-.

Important

- Threaded bushes -3- of steering rack -1- must be inserted in holes -arrows- of subframe -2-.

- Perform basic setting for steering angle sender using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

- Adapt electromechanical power steering using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

Important

- If a new steering rack has been installed:

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - steering rack

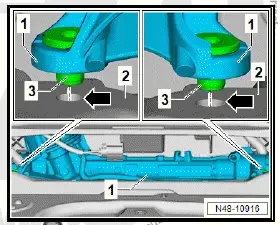

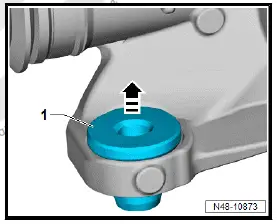

Servicing steering rack

Removing

Power steering control unit - J500- is fitted in steering rack.

Steering rack and power steering control unit - J500- are referred to as steering rack below.

- Remove steering rack ⇒ Rep. gr. 48 ; Removing and installing steering rack .

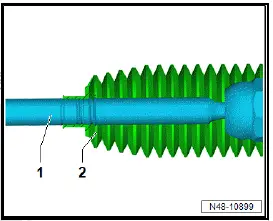

- Drive out threaded bush -1- in direction of -arrow- using a hammer.

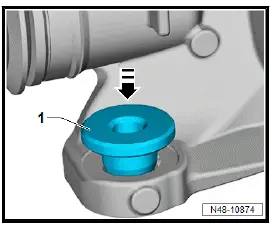

Installing

Installation is carried out in reverse order; note the following:

- Fit threaded bush -1-, making sure it is straight.

- Drive in threaded bush -1- as far as it will go from above using a hammer.

Tightening torques

- ⇒ Rep. gr. 40 ; Exploded view - subframe

- ⇒ Rep. gr. 48 ; Exploded view - steering rack

- ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody trim; Exploded view - underbody trim

Removing and installing boot

Special tools and workshop equipment required

- pinch-on clamp tool for steering rack - VAS 6199A

Removal and installation are described for the left side of vehicle as an example.

Removing

- Remove wheel ⇒ Rep. gr. 44 ; Removing and installing wheel .

- Clean steering rack and track rod on outer side in area of boot using a cleaning cloth.

- Remove track rod ball joint ⇒ Rep. gr. 48 ; Removing and installing track rod ball joint .

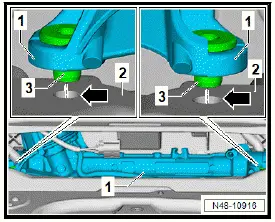

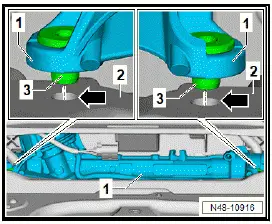

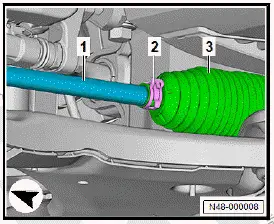

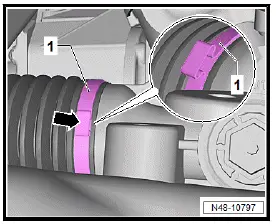

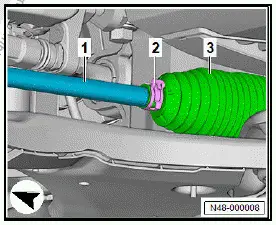

- Open clamp -3- for boot -2- on steering rack -1-.

- Open clamp -2- of boot -3- on track rod -1-.

- Pull off boot -3-.

Installing

Install in reverse order of removal, observing the following:

NOTICE

Check the steering rack for signs of wear.

- The steering rack must be renewed if it shows signs of corrosion, damage, wear or soiling.

- If there is no film of grease on the steering rack, the steering rack must be renewed.

- Do not grease rack.

- Push new clamps and boot onto track rod.

- Lightly grease sealing surface between boot and track rod/ steering rack. For allocation, see ⇒ Electronic parts catalogue (ETKA) .

- Push boot onto steering rack to stop.

- Secure new clamp -1- on boot using pinch-on clamp tool for steering rack - VAS 6199A- .

- Clamp together clamp -1- until it is properly deformed -arrow-.

- Position boot -2- in installation position on outside of track rod -1-.

- Secure clamp -2- of boot -3- on track rod -1-.

- Carry out wheel alignment ⇒ Rep. gr. 44 ; Wheel alignment .

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - track rods

Removing and installing track rod

Special tools and workshop equipment required

- open-end spanner insert - V.A.G 1923-

Removing

Removal and installation are described for the left side of vehicle as an example.

- Remove wheel ⇒ Rep. gr. 44 ; Removing and installing wheel .

- Clean steering rack and track rod on outer side in area of boot using a cleaning cloth.

- Remove track rod ball joint ⇒ Rep. gr. 48 ; Removing and installing track rod ball joint .

- Open clamp -3- for boot -2- on steering rack -1-.

- Pull boot off steering rack -2-, and push it outwards -arrow-.

- Unscrew track rod -1- using open-end spanner insert - V.A.G 1923- .

-

Installing

Install in reverse order of removal, observing the following:

NOTICE

Check the steering rack for signs of wear.

- The steering rack must be renewed if it shows signs of corrosion, damage, wear or soiling.

- If there is no film of grease on the steering rack, the steering rack must be renewed.

- Do not grease rack.

- Screw in and tighten track rod.

- Slightly grease sealing surface between boot and steering rack. Allocation ⇒ Electronic parts catalogue (ETKA) .

- Install boot ⇒ Rep. gr. 48 ; Removing and installing boot .

- Carry out wheel alignment ⇒ Rep. gr. 44 ; Wheel alignment .

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - track rods

Removing and installing track rod ball joint

Special tools and workshop equipment required

- ball joint puller - 3287ARemoving

Removal and installation are described for the left side of vehicle as an example.

- Remove wheel ⇒ Rep. gr. 44 ; Removing and installing wheel .

- Turn steering wheel to full left lock.

- Turn steering as follows:

Important

- For left track rod ball joint, turn steering to full left lock.

- For right track rod ball joint, turn steering to full right lock.

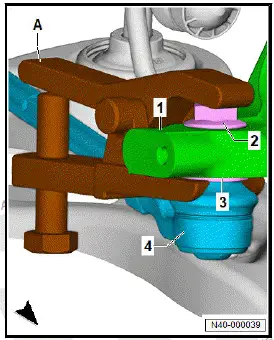

- Mark or measure installation position of track rod ball joint -3- on track rod -1-.

- Loosen nut -2- by counterholding at hexagon -arrow A- on track rod -1-.

- Loosen track rod -1- at track rod ball joint -3-. Use suitable tool on hexagon -arrow A- and -arrow B- to do this.

- Loosen nut -2- on track rod ball joint -4-, but do not unscrew it completely.

- Counterhold on pin using a suitable tool while doing so.

- Unscrew nut -2- only up to end of thread.

NOTICE

Risk of damage to wheel bearing housing! Loosened bushes on wheel bearing housing due to incorrect placement of ball joint puller.

- Position ball joint puller in such a way that fulcrum of bottom support is on bush and not on wheel bearing housing.

- Use ball joint puller - 3287A- -A- to press track rod ball joint -4- off wheel bearing housing -1-. Unscrew nut -2-.

- Unscrew track rod ball joint -3- from track rod -1-.

- Use suitable tool on hexagon -arrow A- and -arrow B- to do this.

Installing

Install in reverse order of removal, observing the following:

- Screw track rod ball joint -3- onto track rod -1- up to previously applied mark, and secure it with nut -2-.

- Carry out wheel alignment ⇒ Rep. gr. 44 ; Wheel alignment .

Tightening torques

- ⇒ Rep. gr. 48 ; Assembly overview - steering rack

- ⇒ Rep. gr. 48 ; Assembly overview - track rods