Volkswagen ID.4: Suspension strut, shock absorber, spring

- Exploded view - shock absorber

- Assembly overview - spring

- Removing and installing shock absorber

- Renewing shock absorber

- Removing and installing spring

- Renewing spring

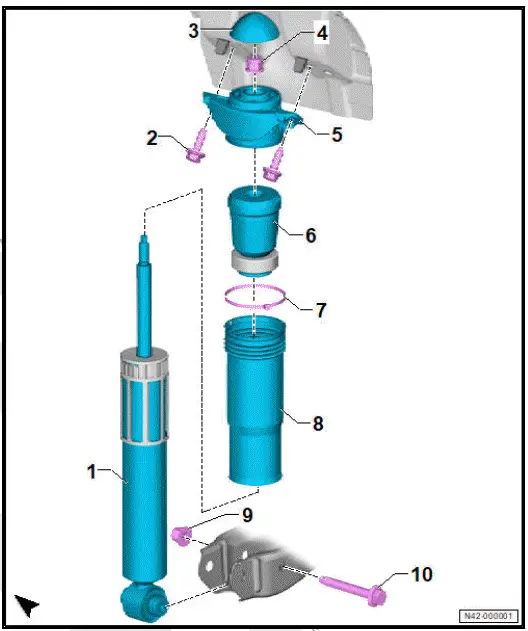

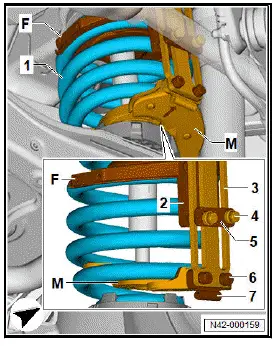

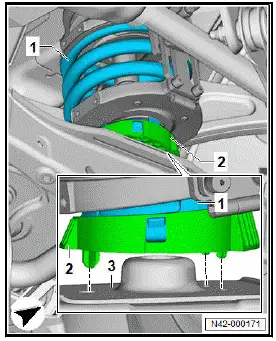

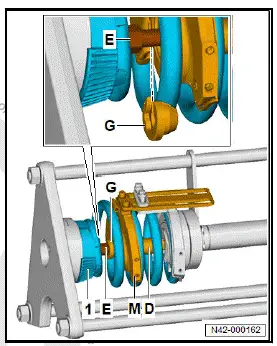

Exploded view - shock absorber

The exploded view here applies to the left side of the vehicle.

- Shock absorber

- ⇒ Rep. gr. 42 ; Removing and installing shock absorber

- Bolt

- 2x

- Renew after removing

- M 10 x 35

- 50 Nm +90º

- Cover

- Nut

- Renew after removing

- M10

- 25 Nm

- Shock absorber mounting

- Bump stop

- Cable tie

- Renew after removing

- Protective tube

- Nut

- Renew after removing

- M 12 x 1.5

- 70 Nm +180º

- Bolt

- Renew after removing

- M 12 x 1.5 x 90

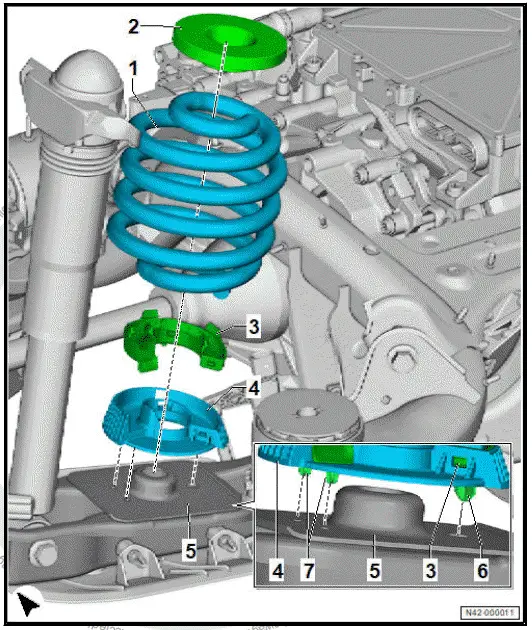

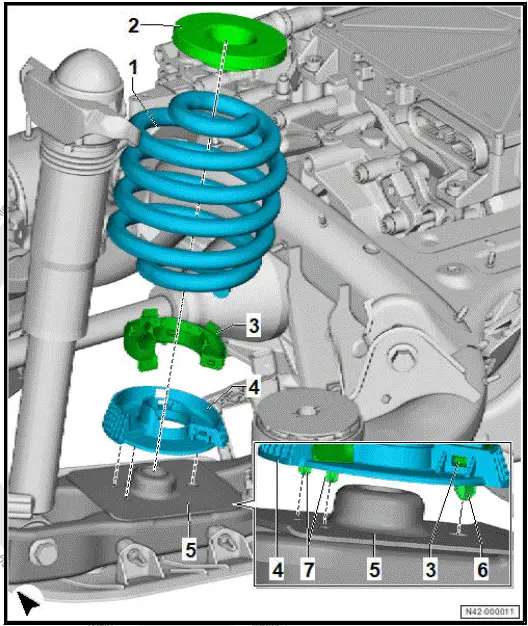

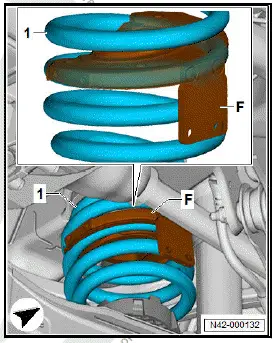

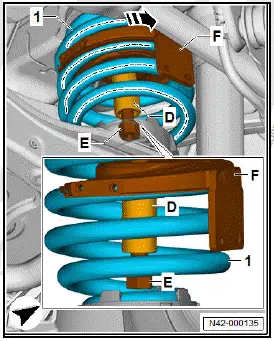

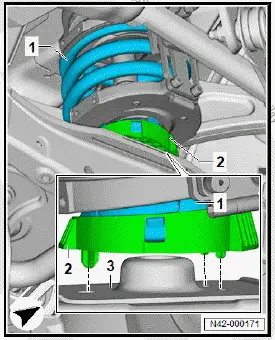

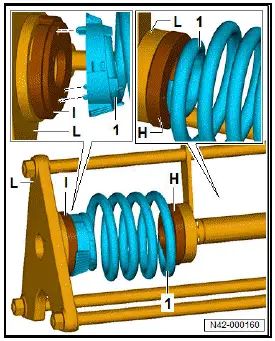

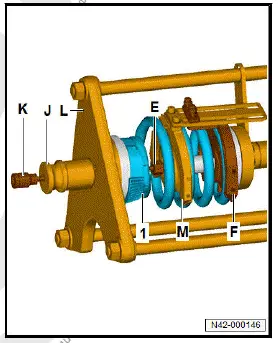

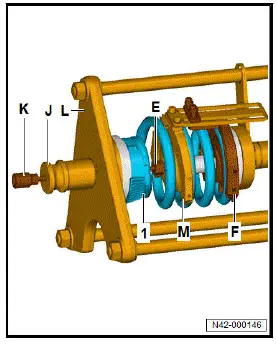

Assembly overview - spring

The overview is shown for the left side of vehicle as an example.

- Shock absorber

- ⇒ Rep. gr. 42 ; Removing and installing shock absorber

- Bolt

- 2x

- Renew after removing

- M 10 x 35

- 50 Nm +90º

- Cover

- Nut

- Renew after removing

- M10

- 25 Nm

- Shock absorber mounting

- Bump stop

- Cable tie

- Renew after removing

- Protective tube

- Nut

- Renew after removing

- M 12 x 1.5

- 70 Nm +180º

- Bolt

- Renew after removing

- M 12 x 1.5 x 90

Removing and installing shock absorber

The overview is shown for the left side of vehicle as an example.

- Spring

- Depending on equipment/ version

- Allocation ⇒ Electronic parts catalogue (ETKA)

- ⇒ Rep. gr. 42 ; Removing and installing spring

- Spring seat

- Support

- Spring seat

- Spring control arm

- ⇒ Rep. gr. 42 ; Assembly overview - spring control arm

- ⇒ Rep. gr. 42 ; Removing and installing spring control arm

- Retaining clip

- Guides

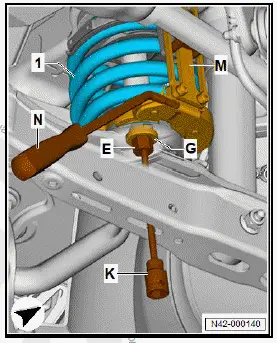

Removing and installing shock absorber

Special tools and workshop equipment required

- engine and gearbox jack - VAS 6931-

Removing

Removal and installation are described for the left side of vehicle as an example.

- Remove wheel ⇒ Rep. gr. 44 ; Removing and installing wheel .

- ⇒ Rep. gr. 42 ; Secure vehicle to support arms of lifting platform .

- Unbolt rear left vehicle level sender - G76- from spring control arm ⇒ Rep. gr. 43 ; Removing and installing rear vehicle level sender [G76]/[G77] .

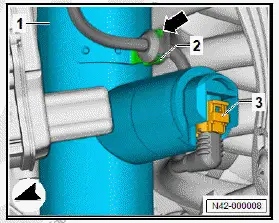

Vehicles with adaptive chassis control

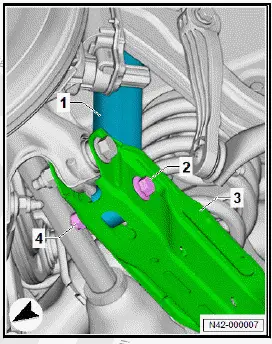

- Disconnect electrical connector -3- on rear left shock absorber damping adjustment valve - N338- .

- Pull electrical wire -arrow- off retainer on shock absorber -2-.

All vehicles (continued)

- Position engine and gearbox jack - VAS 6931- under spring control arm, and push upwards.

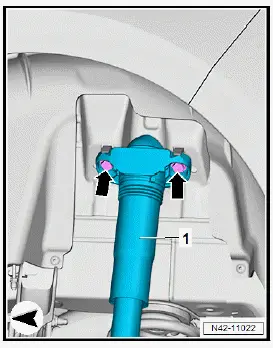

- Unscrew bolts -arrows- for shock absorber -1-.

- Unscrew nut -4-.

- Pull out bolt -2-.

- Press together shock absorber -1-.

- Guide shock absorber -1- out of spring control arm -3-.

Installing

Install in reverse order of removal, observing the following:

Important

- The shock absorber must be bolted to the spring control arm only in unladen position ⇒ Rep. gr. 42 ; Raising wheel bearing assembly to unladen position .

- Carry out required function/functions using ⇒ Vehicle diagnostic tester ⇒ Rep. gr. 00 ; Access to diagnoses .

Tightening torques

- ⇒ Rep. gr. 42 ; Assembly overview - shock absorber

- ⇒ Rep. gr. 43 ; Assembly overview - rear vehicle level senders

Renewing shock absorber

Special tools and workshop equipment required

- Extension - T10001/14-

- Extension - T10001/3-

- Ratchet - T10001/11-

- Suspension strut support clamp - V.A.G 1752/20-

- Torque wrench - V.A.G 1331-

- shock absorber set - T10001-

- suspension strut support clamp - V.A.G 1752/20-

Remove shock absorber ⇒ Rep. gr. 42 ; Removing and installing shock absorber .

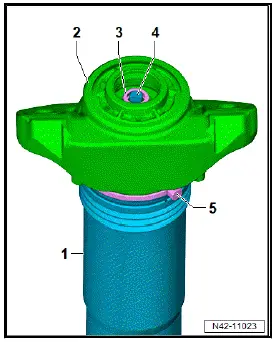

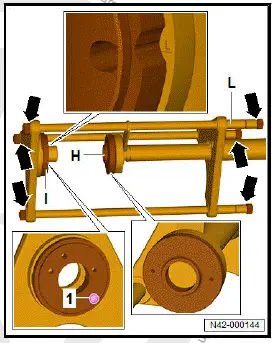

Dismantling shock absorber

- Clamp suspension strut support clamp - V.A.G 1752/20- in a vice.

- Clamp shock absorber into suspension strut support clamp - V.A.G 1752/20- .

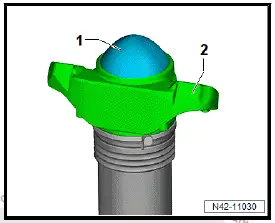

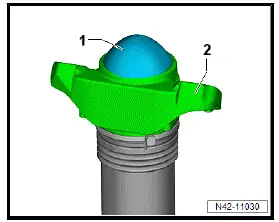

- Lever cover -1- off shock absorber mounting -2-.

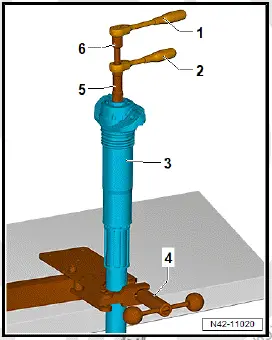

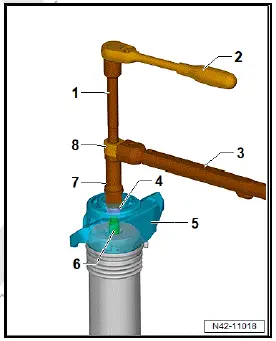

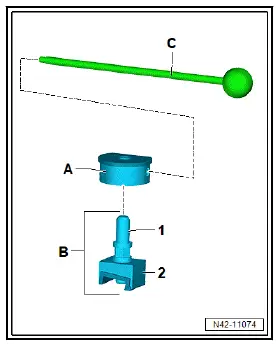

- Fit tools from shock absorber set - T10001- as shown in illustration, and loosen threaded connection for shock absorber mounting.

- Commercially available ratchet

- Ratchet - T10001/11-

- Shock absorbers

- Suspension strut support clamp - V.A.G 1752/20-

- Extension - T10001/3-

- Extension - T10001/14-

- Open cable tie -5-.

- Unscrew nut -3-.

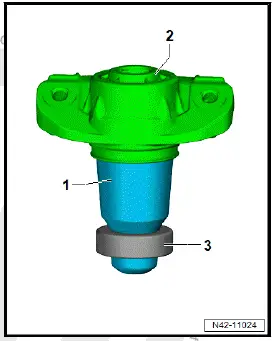

- Pull shock absorber mounting -2- off shock absorber -1-.

- Remove protective tube -1- from shock absorber mounting -2-.

- Remove protective tube -1-.

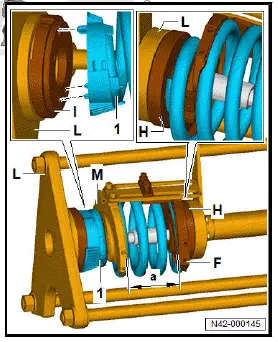

Assembling shock absorber

- Fit tools from shock absorber set - T10001- as shown in illustration, and tighten threaded connection. When doing this, counterhold using ratchet.

- Tool insert - T10001/14-

- Commercially available ratchet

- Torque wrench - V.A.G 1331-

- Nut

- Shock absorber mounting

- Piston rod

- Extension - T10001/3-

- Ring spanner insert AF 21, commercially available

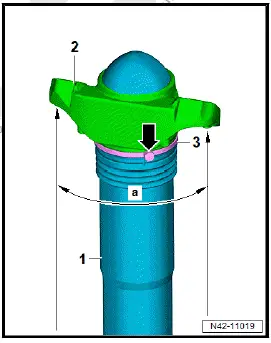

- Insert stop buffer -1- to stop into shock absorber mounting -2-.

- Make sure that seal -3- is firmly seated.

- Push protective tube -1- to stop onto shock absorber mounting -2-.

- Fit and secure cable tie -3-.

Important

- The fastener -arrow- of the cable tie -3- must be located within area -a-.

- Closure -arrow- of cable tie must point outwards when shock absorber is installed.

- Install cover -1- to shock absorber mounting -2-, and ensure that it is seated firmly.

Tightening torques

- ⇒ Rep. gr. 42 ; Assembly overview - shock absorber

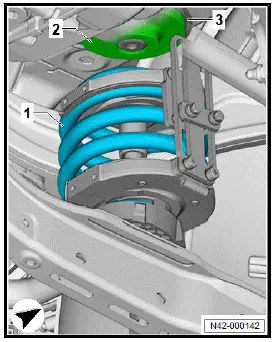

Removing and installing spring

Special tools and workshop equipment required

- Spreader device - VAS 6274/8-

- Supplement set - VAS 6274/12-

- Supplement set - VAS 6274/15A-

- Thrust plates - VAS 6274/16-

- spring compressing system - VAS 6274-

Removal and installation are described for the left side of vehicle as an example.

Removing

- Remove wheel ⇒ Rep. gr. 44 ; Removing and installing wheel .

- ⇒ Rep. gr. 42 ; Secure vehicle to support arms of lifting platform .

- Remove stone deflector for spring control arm ⇒ Rep.

gr. 42 ; Removing and installing stone deflector for spring control arm .

- Remove rear centre underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing rear centre underbody cladding .

- Remove rear underbody cladding ⇒ General body repairs, exterior; Rep. gr. 66 ; Underbody cladding; Removing and installing rear underbody cladding .

Vehicles with rear left vehicle level sender - G76-

- Unbolt rear left vehicle level sender - G76- from spring control arm ⇒ Rep. gr. 43 ; Removing and installing rear vehicle level sender [G76]/[G77] .

All vehicles (continued)

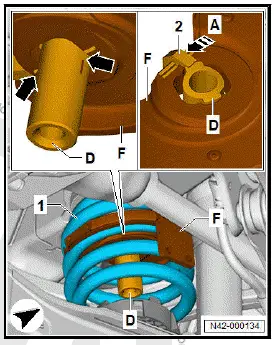

Preparing spreader device for rear suspension link:

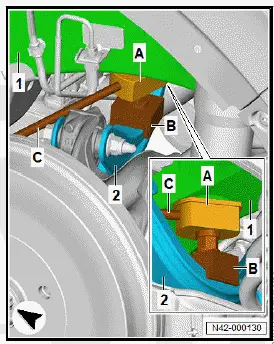

- Screw threaded spindle -1- from spreader device - VAS 6274/8- into plastic-padded plate -2- from spreader device - VAS 6274/8- .

- Screw support plate - VAS 6274/15-8- -A- onto threaded spindle -1-.

- Screw in gripping rod included with spreader device - VAS 6274/8- -C-.

Important

- Please pay attention to the relevant side of the vehicle.

All vehicles (continued)

- Position support plate -A- on longitudinal member -1-.

- Fit support plate -B- onto suspension link at upper front -2-.

- Align tools between upper front suspension link -2- and longitudinal member -1- via gripping rod -1-.

- Turn threaded spindle until both support plates make contact.

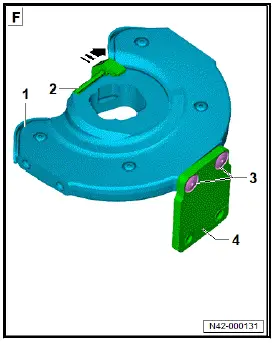

- Push slide lock -2- in direction of -arrow-.

- Secure locating element -4- to thrust plate with slide lock - VAS 6274/16-2- -1- using bolts -3-.

Important

- Tighten bolts -3- to 10 Nm.

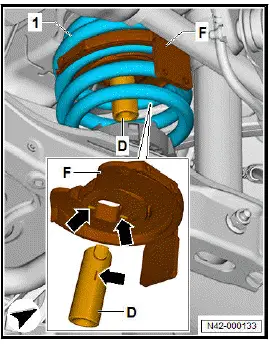

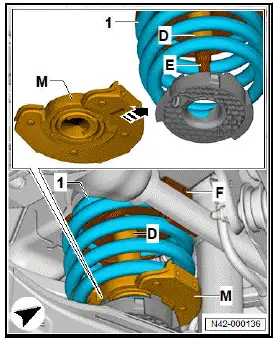

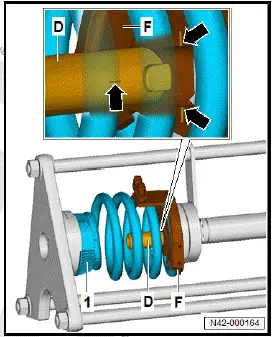

- Insert thrust plate with slide lock - VAS 6274/16-2- -F- into spring -1- at bottom.

Important

- Plastic support must face downwards.

- Turn thrust plate with slide lock -F- upwards at spring -1-.

- Insert 69 mm piston - VAS 6274/12-6- -D- into thrust plate with slide lock -F-.

Important

- Markings on piston -D- and thrust plate with slide lock -Fmust be offset relative to one another by 90º.

- Push piston -D- through thrust plate with slide lock -F-.

- Turn piston -D- by 90º.

- Pull piston -D- downwards into guides on thrust plate with slide lock -F-.

Important

- Markings -arrows- must align properly.

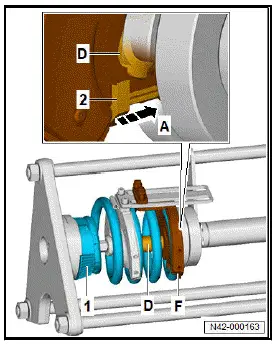

- Push slide lock -2- to stop in direction of -arrow A-. This will fix piston -D- in position.

- Turn thrust plate with slide lock -F- as far as possible upwards on spring coils -1-.

- Make sure when doing this that plastic support rests against spring coils -1-.

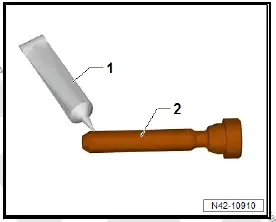

NOTICE

Risk of damage to spindle due to lacking or wrong grease.

- Apply a thin coat of molybdenum disulfide to the front area of the spindle.

- Apply a thin coat of molybdenum disulfide -1- to the front area of the spindle -2-. For allocation, refer to ⇒ Operating manual of spring compressing system - VAS 6274- .

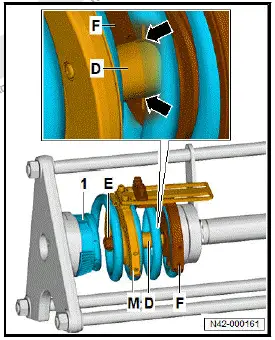

- Guide spindle - VAS 6274/15-1A- -E- into spring -1-, and screw into piston -D-.

- Insert thrust plate with swivel mounting - VAS 6274/16-1- -M- into spring -1-.

Important

- Plastic support must face upwards.

- Turn thrust plate with swivel mounting -M- upwards at spring -1-.

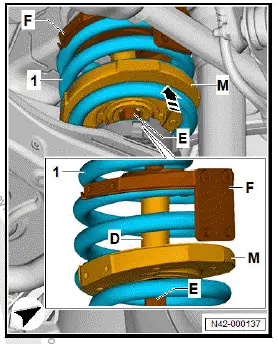

- Guide hexagon of spindle -E- through hole in thrust plate with swivel mounting -M-.

- Guide spindle -E- with socket with ball head (AF8) - VAS 6274/15-3- .

- Unscrew spindle -E- as far as possible.

Important

- Shank - without spindle threads - -E- must be located below thrust plate with swivel mounting -M-.

- Position spindle attachment - VAS 6274/15-2A- -G- on spindle -E-.

- Turn thrust plate with swivel mounting -M- as far as possible downwards at spring -1-.

- Turn thrust plate with swivel mounting -M- upwards at spring coil -1-.

- Align spindle attachment -G- in thrust plate with swivel mounting -M-.

Important

- Make sure that spindle attachment -G- makes proper contact with guide of thrust plate with swivel mounting -M-.

- Align thrust plate with slide lock -F- and thrust plate with swivel mounting -M-.

Important

- Arrow on thrust plate with swivel mounting -M- must face in direction of travel.

Important

- Make sure that spring is properly seated in thrust plates.

- Secure locating element -3- with bracket -7- to thrust plate with swivel mounting -M- -5-.

Important

- Tighten bolts -6- to 10 Nm.

- Connect thrust plate with swivel mounting -M- and thrust plate with slide lock -F- via brackets -5- and bolts -4-.

Important

- Tighten bolts -4- to 10 Nm.

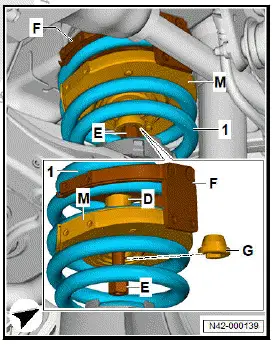

- Position socket with ball head (AF8) - VAS 6274/15-3- -K- at spindle -E-.

Important

- Make sure that spindle attachment -G- is correctly seated in swivel mounting of thrust plate -M-.

- Make sure that spring -1- is properly seated in thrust plate with swivel mounting -M-.

- Tighten spindle -E- by hand.

- Insert counter-hold tool - VAS 6274/7- -N- into thrust plate with swivel mounting -M-.

- Tension spring -1- using socket wrench -K- while counterholding with counter-hold tool -N-.

- Compress spring -1- until support -2- can be removed.

- Carefully lever spring -1- with spring seat -2- off spring control arm -3-.

- Remove spring -1- with tools.

Installing

Install in reverse order of removal, observing the following:

- Insert lug of spring seat -2- into hole in spring control arm -3-.

Renewing spring

Special tools and workshop equipment required

- Spreader device - VAS 6274/8-

- Supplement set - VAS 6274/12-

- Supplement set - VAS 6274/15A-

- Thrust plates - VAS 6274/16-

- foot pump - VAS 6179-

- hydraulic tensioning device - VAS 6274/9-

Removing

- Remove spring ⇒ Rep. gr. 42 ; Removing and installing spring .

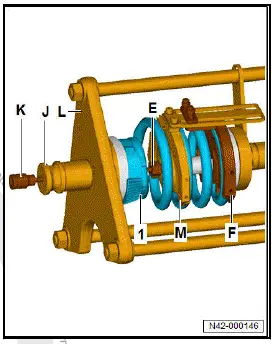

- Connect foot pump - VAS 6179- to hydraulic tensioning device - VAS 6274/9- .

- Check nuts -arrows- on hydraulic tensioning device - VAS 6274/9- -L- for secure fit.

- Attach centring disc of spring mounting - VAS 6274/15-6A- -I- to tensioning device -L-.

Important

- Make sure that recess of centring disc -I- faces towards vehicle side L or R, respectively, and that locating element is fitted at top.

- Secure centring disc -9- with bolt -1-.

- Place adapter plate with magnets - VAS 6274/15-5- -H- onto flexible mounting, making sure that magnetic holder is correctly seated.

- Insert spring -1- with tools into tensioning device -L-.

Important

- Make sure that guides on mounting -1- are located in holes of centring disc -I-.

- Hold spring in this position.

- Connect foot pump -L- to tensioning device.

- Withdraw piston of tensioning device -L- until spring -1- is securely fitted.

Important

- Do not tension spring -1-.

- Spring -1- must be seated correctly at guide of adapter plate -H-.

- Determine and make note of dimension -a-.

- Mark installation position of thrust plate with slide lock - VAS 6274/16-2- -F- and thrust plate with swivel mounting - VAS 6274/16-1- -M- on spring -1-.

- Fit centring sleeve - VAS 6274/15-7- -J- in position.

- Position socket with ball head (AF8) - VAS 6274/15-3- -K- on spindle 130 mm (AF19) - VAS 6274/15-1A- -E-.

- Relieve tension from spring -1- via socket -K- at tensioning device -L-.

- Move back piston of tensioning device -L- using foot pump.

- Make sure that spring -1- is properly seated in tensioning device -L-.

- Relieve tension from spring -1- via socket -K- in tensioning device -L-.

- Move piston of tensioning device -L- further back via foot pump.

- Detach tools.

Installing

Install in reverse order of removal, observing the following:

- Insert spring -1- into tensioning device -L-.

Important

- Markings must be transferred to new coil spring.

- Make sure that guides on mounting -1- are located in holes of centring disc -I-.

- Hold spring in this position.

- Connect foot pump -L- to tensioning device.

- Withdraw piston of tensioning device -L- as far as spring -1-.

Important

- Spring -1- must NOT be tensioned.

- Make sure that spring -1- is properly seated on guide of adapter plate -M-.

- Retract piston of tensioning device -L- until spring -1- is securely fitted.

- Insert thrust plate -F- in installation position.

- Move 69 mm piston - VAS 6274/12-6- -D- through thrust plate -F-.

- Insert piston -D- into thrust plate -F-.

Important

- Markings -arrow- on piston -D- and thrust plate -F- must be offset 90ºrelative to one another.

- Turn piston -D- by 90º.

- Pull piston -D- downwards into guides on thrust plate -F-.

Important

- Markings -arrows- must align properly.

- Insert thrust plate -M- observing markings for orientation.

- Screw spindle -E- into piston -D- using socket with ball head (AF8) - VAS 6274/15-3- .

- Attach locating element.

Important

- Tighten bolts to 10 Nm.

- Push slide lock -2- to stop in direction of -arrow A-. This will fix piston -D- in position.

- Push spindle attachment - VAS 6274/15-2A- -G- onto spindle -E-.

- Screw spindle -E- further into piston -D-.

- Screw in spindle -E- until spindle attachment -G- rests against thrust plate -M-.

- Make sure that spindle attachment -G- is correctly seated in hole of thrust plate -M-.

- Fit centring sleeve - VAS 6274/15-7- -J- in position.

- Bring socket -K- in position on spindle -E-.

Important

- Spring -1- must be properly seated in tensioning device -L-.

- Turn socket -K- 2 turns.

- Turn socket -K- far enough to make sure that spring -1- cannot slip out of tensioning device -L-.

Important

- Spring -1- and tools must be seated correctly.

- Operate foot pump, and slightly tighten spring -1- via piston of tensioning device -L-.

- Tension spring -1- via spindle -E-. Keep retracting piston of tensioning device -L- over and over again.

- Tension spring -1- until dimension a determined beforehand is obtained.

- Move back piston of tensioning device -L- via foot pump.

- Hold spring -1- in place.

- Remove spring -1- with tools from tensioning device -L-.

- Install spring ⇒ Rep. gr. 42 ; Removing and installing spring .

Volkswagen ID.4 (E21) 2021-2026 Service Manual

Suspension strut, shock absorber, spring

- Exploded view - shock absorber

- Assembly overview - spring

- Removing and installing shock absorber

- Renewing shock absorber

- Removing and installing spring

- Renewing spring

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image